This item is non-discoverable

Akar, Samet

Loading...

Profile URL

Name Variants

S., Akar

Akar, Samet

Samet, Akar

A., Samet

Akar,S.

S.,Akar

A.,Samet

Akar, Samet

Samet, Akar

A., Samet

Akar,S.

S.,Akar

A.,Samet

Job Title

Doktor Öğretim Üyesi

Email Address

samad.nadimi@atilim.edu.tr

Main Affiliation

Department of Mechanical Engineering

Status

Former Staff

Website

ORCID ID

Scopus Author ID

Turkish CoHE Profile ID

Google Scholar ID

WoS Researcher ID

Sustainable Development Goals

9

INDUSTRY, INNOVATION AND INFRASTRUCTURE

2

Research Products

This researcher does not have a Scopus ID.

This researcher does not have a WoS ID.

Scholarly Output

5

Articles

4

Views / Downloads

19/361

Supervised MSc Theses

1

Supervised PhD Theses

0

WoS Citation Count

15

Scopus Citation Count

23

WoS h-index

2

Scopus h-index

3

Patents

0

Projects

0

WoS Citations per Publication

3.00

Scopus Citations per Publication

4.60

Open Access Source

0

Supervised Theses

1

Google Analytics Visitor Traffic

| Journal | Count |

|---|---|

| Artificial Intelligence for Engineering Design, Analysis and Manufacturing | 1 |

| International Journal of Mechatronics and Manufacturing Systems | 1 |

| Machining Science and Technology | 1 |

| The International Journal of Advanced Manufacturing Technology | 1 |

Current Page: 1 / 1

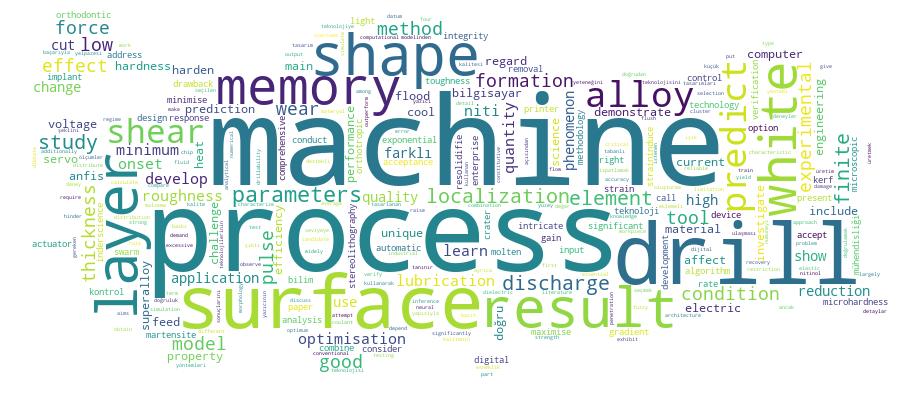

Competency Cloud