Lotfısadıgh, Bahram

Loading...

Profile URL

Name Variants

Lotfisadigh, B.

Lotfısadıgh, Bahram

Bahram, Lotfısadıgh

Lotfisadigh, Bahram

L.,Bahram

B.,Lotfisadigh

L., Bahram

Bahram, Lotfisadigh

B., Lotfisadigh

B.,Lotfısadıgh

Lotfısadıgh,B.

Lotfisadigh,B.

Sadigh, Bahram Lotfi

Lotfısadıgh, Bahram

Bahram, Lotfısadıgh

Lotfisadigh, Bahram

L.,Bahram

B.,Lotfisadigh

L., Bahram

Bahram, Lotfisadigh

B., Lotfisadigh

B.,Lotfısadıgh

Lotfısadıgh,B.

Lotfisadigh,B.

Sadigh, Bahram Lotfi

Job Title

Doktor Öğretim Üyesi

Email Address

bahram.lotfisadigh@atilim.edu.tr

Main Affiliation

Manufacturing Engineering

Status

Former Staff

Website

ORCID ID

Scopus Author ID

Turkish CoHE Profile ID

Google Scholar ID

WoS Researcher ID

Sustainable Development Goals

2

ZERO HUNGER

0

Research Products

11

SUSTAINABLE CITIES AND COMMUNITIES

1

Research Products

14

LIFE BELOW WATER

0

Research Products

6

CLEAN WATER AND SANITATION

0

Research Products

1

NO POVERTY

0

Research Products

5

GENDER EQUALITY

0

Research Products

9

INDUSTRY, INNOVATION AND INFRASTRUCTURE

6

Research Products

16

PEACE, JUSTICE AND STRONG INSTITUTIONS

0

Research Products

17

PARTNERSHIPS FOR THE GOALS

0

Research Products

15

LIFE ON LAND

1

Research Products

10

REDUCED INEQUALITIES

0

Research Products

7

AFFORDABLE AND CLEAN ENERGY

0

Research Products

8

DECENT WORK AND ECONOMIC GROWTH

0

Research Products

4

QUALITY EDUCATION

0

Research Products

12

RESPONSIBLE CONSUMPTION AND PRODUCTION

1

Research Products

3

GOOD HEALTH AND WELL-BEING

1

Research Products

13

CLIMATE ACTION

0

Research Products

This researcher does not have a Scopus ID.

This researcher does not have a WoS ID.

Scholarly Output

22

Articles

12

Views / Downloads

141/2129

Supervised MSc Theses

5

Supervised PhD Theses

1

WoS Citation Count

227

Scopus Citation Count

276

WoS h-index

11

Scopus h-index

12

Patents

0

Projects

0

WoS Citations per Publication

10.32

Scopus Citations per Publication

12.55

Open Access Source

5

Supervised Theses

6

Google Analytics Visitor Traffic

| Journal | Count |

|---|---|

| Machining Science and Technology | 3 |

| International Journal of Computer Integrated Manufacturing | 2 |

| Procedia CIRP | 2 |

| The International Journal of Advanced Manufacturing Technology | 2 |

| Artificial Intelligence for Engineering Design, Analysis and Manufacturing: AIEDAM | 1 |

Current Page: 1 / 3

Scopus Quartile Distribution

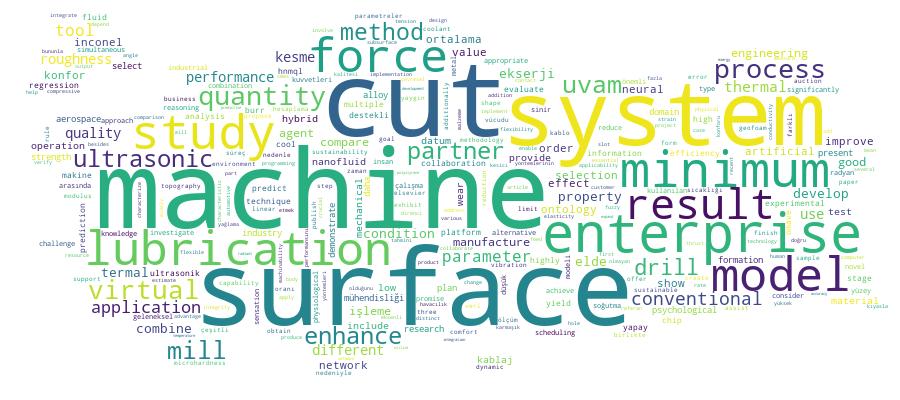

Competency Cloud

12 results

Scholarly Output Search Results

Now showing 1 - 10 of 12

Article Citation - WoS: 15Citation - Scopus: 20A Survey of Partner Selection Methodologies for Virtual Enterprises and Development of a Goal Programming-Based Approach(Springer London Ltd, 2016) Nikghadam, Shahrzad; Sadigh, Bahram Lotfi; Ozbayoglu, Ahmet Murat; Unver, Hakki Ozgur; Kilic, Sadik EnginA virtual enterprise (VE) is a platform that enables dynamic collaboration among manufacturers and service providers with complementary capabilities in order to enhance their market competitiveness. The performance of a VE as a system depends highly on the performance of its partner enterprises. Hence, choosing an appropriate methodology for evaluating and selecting partners is a crucial step toward creating a successful VE. In this paper, we begin by presenting an extensive review of articles that address the VE partner selection problem. To fill a significant research gap, we develop a new goal programming (GP)-based approach that can be applied in extreme bidding conditions such as tight delivery timelines for large demand volumes. In this technique, fuzzy analytic hierarchy process (F-AHP) is used to determine customer preferences for four main criteria: proposed unit price, on-time delivery reliability, enterprises' past performance, and service quality. These weights are then incorporated into the GP model to evaluate bidders based on customers' preferences and goals. We present a case study in which we implement the F-AHP-GP technique and verify the model's applicability, as it provides a more flexible platform for matching customers' preferences.Article Citation - WoS: 13Citation - Scopus: 14Integration of Psychological Parameters Into a Thermal Sensation Prediction Model for Intelligent Control of the Hvac Systems(Elsevier Science Sa, 2023) Turhan, Cihan; Ozbey, Mehmet Furkan; Lotfi, Bahram; Akkurt, Gulden GokcenConventional thermal comfort models take physiological parameters into account on thermal comfort models. On the other hand, psychological behaviors are also proven as a vital parameter which affects the thermal sensation. In the literature, limited studies which combine both physiological and psychological parameters on the thermal sensation models are exist. To this aim, this study develops a novel Thermal Sensation Prediction Model (TSPM) in order to control the HVAC system by considering both parameters. A data-driven TSPM, which includes Fuzzy Logic (FL) model, is developed and coded using Phyton language by the authors. Two physiological parameters (Mean Radiant Temperature and External Temperature) and one psychological parameter (Emotional Intensity Score (EIS) including Vigour, Depression, Tension with total of 32 subscales) are selected as inputs of the model. Besides the physiological parameters which are decided intentionally considering a manual ventilated building property, the most influencing three sub- psychological parameters on thermal sensation are also selected in the study. While the physiological parameters are measured via environmental data loggers, the psychological parameters are collected simultaneously by the Profile of Mood States questionnaire. A total of 1159 students are participated to the questionnaire at a university study hall between 15th of August 2021 and 15th of September 2022. The results showed that the novel model predicted Thermal Sensation Vote (TSV) with an accuracy of 0.92 of R2. The output of this study may help to develop an integrated Heating Ventilating and Air Conditioning (HVAC) system with Artificial Intelligence - enabled Emulators that also includes psychological parameters.Article Citation - WoS: 25Citation - Scopus: 26Machining Performance and Sustainability Analysis of Al2o3< Hybrid Nanofluid Mql Application for Milling of Ti-6al(Taylor & Francis inc, 2024) Lotfi, Bahram; Namlu, Ramazan Hakki; Kilic, S. EnginMachining of Ti-6Al-4V presents challenges due to its low thermal conductivity, and conventional cutting fluids (CCF) are inadequate in providing a productive and sustainable solution. This study aims to achieve more sustainable and productive machining of Ti-6Al-4V by utilizing Al2O3 and CuO-added Nanofluid Minimum Quantity Lubrication (NMQL) individually and in hybrid form with different concentrations. A comparison is made with pure-MQL, CCF and dry conditions. The study consists of three stages. In the first stage, the physical properties of the coolants, like contact angle and surface tension, are investigated. The second stage involves slot milling operations, and various outputs including cutting forces, surface roughness, surface topography, surface finish, and subsurface microhardness are analyzed. In the last stage, a sustainability analysis is conducted based on the Pugh Matrix Approach. The results indicate that Al2O3-NMQL exhibits lower contact angles and surface tensions compared to other conditions. Furthermore, HNMQL applications result in lower cutting forces (up to 46.5%), surface roughness (up to 61.2%), and microhardness (up to 6.6%), while yielding better surface finish and topography compared to CCF. The sustainability analysis demonstrates that HNMQL application is the most suitable option for achieving sustainable machining of Ti-6Al-4V.Article Citation - WoS: 39Citation - Scopus: 41Enhancing Machining Efficiency of Ti-6al Through Multi-Axial Ultrasonic Vibration-Assisted Machining and Hybrid Nanofluid Minimum Quantity Lubrication(Elsevier Sci Ltd, 2024) Namlu, Ramazan Hakki; Lotfi, Bahram; Kilic, S. EnginTi-6Al-4V offers a balance of good strength with lightweight properties. Yet, Ti-6Al-4V poses machining challenges, including low thermal conductivity, chemical adhesion to cutting tools, and chip removal difficulties. To improve machining efficiency, Ultrasonic Vibration-Assisted Machining (UVAM) has emerged as a promising approach. UVAM has demonstrated reduced tool wear, cutting forces, and improved surface quality compared to Conventional Machining (CM). Additionally, Minimum Quantity Lubrication (MQL) methods offer sustainable coolant alternatives, with recent research focusing on Nanofluid-MQL (NMQL) and Hybrid Nanofluid-MQL (HNMQL) for enhanced performance. Although there exists a body of literature showcasing the promising effects of UVAM and MQL methods individually, comprehensive investigations into the synergistic effects of these methodologies remain limited. This study addresses these critical research gaps by conducting a systematic examination of combined application of multi-axial UVAM and HNMQL. Specifically, it delves into the comparison of different vibration directions within UVAM, evaluates the effectiveness of UVAM when combined with cutting fluids incorporating Al2O3 and CuO nanoparticles in NMQLs and HNMQLs, and contrasts these novel approaches with conventional machining methods. The study unfolds in three distinct stages. The first stage examines the ultrasonic cutting mechanism and its combined application with the MQL technique. In the second stage, the study investigates the physical properties of the cutting fluids, including contact angle and surface tension. The final stage encompasses slot milling operations, where an array of parameters such as cutting forces, surface roughness, surface topography, surface texture, and the occurrence of burr formations are rigorously analyzed. The results demonstrate that the combination of multi-axial UVAM with HNMQL yields substantial advantages over traditional machining methods. Notably, it leads to a remarkable reduction in cutting forces (up to 37.6 %) and surface roughness (up to 37.4 %). Additionally, this combination engenders the production of highly homogeneous and uniform surface textures, characterized by minimal surface defects and a significantly diminished occurrence of burr formations. These findings underscore the potential of multi-axial UVAM combined with HNMQL as a promising approach in enhancing the machining of Ti-6Al-4V, thus offering a pathway to enhance the efficiency and precision of aerospace component manufacturing processes.Article Citation - WoS: 7Citation - Scopus: 10Combined Use of Ultrasonic-Assisted Drilling and Minimum Quantity Lubrication for Drilling of Niti Shape Memory Alloy(Taylor & Francis inc, 2023) Namlu, Ramazan Hakki; Lotfi, Bahram; Kilic, S. Engin; Yilmaz, Okan Deniz; Akar, SametThe drilling of shape-memory alloys based on nickel-titanium (Nitinol) is challenging due to their unique properties, such as high strength, high hardness and strong work hardening, which results in excessive tool wear and damage to the material. In this study, an attempt has been made to characterize the drillability of Nitinol by investigating the process/cooling interaction. Four different combinations of process/cooling have been studied as conventional drilling with flood cooling (CD-Wet) and with minimum quantity lubrication (CD-MQL), ultrasonic-assisted drilling with flood cooling (UAD-Wet) and with MQL (UAD-MQL). The drill bit wear, drilling forces, chip morphology and drilled hole quality are used as the performance measures. The results show that UAD conditions result in lower feed forces than CD conditions, with a 31.2% reduction in wet and a 15.3% reduction in MQL on average. The lowest feed forces are observed in UAD-Wet conditions due to better coolant penetration in the cutting zone. The UAD-Wet yielded the lowest tool wear, while CD-MQL exhibited the most severe. UAD demonstrated a & SIM;50% lower tool wear in the wet condition than CD and a 38.7% in the MQL condition. UAD is shown to outperform the CD process in terms of drilled-hole accuracy.Article Citation - WoS: 13Citation - Scopus: 16An Experimental Study on Ultrasonic-Assisted Drilling of Inconel 718 Under Different Cooling/Lubrication Conditions(Springer London Ltd, 2024) Erturun, Omer Faruk; Tekaut, Hasan; Cicek, Adem; Ucak, Necati; Namlu, Ramazan Hakki; Lotfi, Bahram; Kilic, S. EnginUltrasonic-assisted drilling (UAD) is one of the efficient and innovative methods to improve the drillability of difficult-to-cut materials. In the present study, the UAD of Inconel 718 was investigated under different cooling and/or lubrication conditions. The drilling tests were carried out at a constant cutting speed (15 m/min) and a feed (0.045 mm/rev) using uncoated and TiAlN-coated solid carbide drills under dry, conventional cutting fluid (CCF), and minimum quantity lubrication (MQL) conditions. The applicability of UAD to drilling Inconel 718 was evaluated in terms of thrust force, surface roughness, roundness error, burr formation, subsurface microstructure and microhardness, tool wear, and chip morphology. The test results showed that, when compared to conventional drilling (CD), UAD reduced the thrust force and improved the hole quality, tool life, and surface integrity under all conditions. Good surface finish, lower roundness error, and minimum burr heights were achieved under CCF conditions. MQL drilling provided lower thrust forces, better tool performance, and good subsurface quality characteristics. In addition, the simultaneous application of CCF-UAD and MQD-UAD showed significantly better performance, especially when using the coated tool.Article Citation - WoS: 12Citation - Scopus: 13Predictive Models for Mechanical Properties of Expanded Polystyrene (eps) Geofoam Using Regression Analysis and Artificial Neural Networks(Springer London Ltd, 2022) Akis, E.; Guven, G.; Lotfisadigh, B.Initial elastic modulus and compressive strength are the two most important engineering properties for modeling and design of EPS geofoams, which are extensively used in civil engineering applications such as light-fill material embankments, retaining structures, and slope stabilization. Estimating these properties based on geometric and physical parameters is of great importance. In this study, the compressive strength and modulus of elasticity values are obtained by performing 356 unconfined compression tests on EPS geofoam samples with different shapes (cubic or disc), dimensions, loading rates, and density values. Using these test results, the mechanical properties of the specimens are predicted by linear regression and artificial neural network (ANN) methods. Both methods predicted the initial modulus of elasticity (E-i), 1% strain (sigma(1)), 5% strain (sigma(5)), and 10% strain (sigma(10)) strength values on a satisfactory level with a coefficient of correlation (R-2) values of greater than 0.901. The only exception was in prediction of sigma(1) and E-i in disc-shaped samples by linear regression method where the R-2 value was around 0.558. The results obtained from linear regression and ANN approaches show that ANN slightly outperform linear regression prediction for E-i and sigma(1) properties. The outcomes of the two methods are also compared with results of relevant studies, and it is observed that the calculated values are consistent with the results from the literature.Article Citation - WoS: 13Citation - Scopus: 17Cutting Force Prediction in Ultrasonic-Assisted Milling of Ti-6al With Different Machining Conditions Using Artificial Neural Network(Cambridge University Press, 2021) Namlu,R.H.; Turhan,C.; Sadigh,B.L.; Kiliç,S.E.Ti-6Al-4V alloy has superior material properties such as high strength-to-weight ratio, good corrosion resistance, and excellent fracture toughness. Therefore, it is widely used in aerospace, medical, and automotive industries where machining is an essential process for these industries. However, machining of Ti-6Al-4V is a material with extremely low machinability characteristics; thus, conventional machining methods are not appropriate to machine such materials. Ultrasonic-assisted machining (UAM) is a novel hybrid machining method which has numerous advantages over conventional machining processes. In addition, minimum quantity lubrication (MQL) is an alternative type of metal cutting fluid application that is being used instead of conventional lubrication in machining. One of the parameters which could be used to measure the performance of the machining process is the amount of cutting force. Nevertheless, there is a number of limited studies to compare the changes in cutting forces by using UAM and MQL together which are time-consuming and not cost-effective. Artificial neural network (ANN) is an alternative method that may eliminate the limitations mentioned above by estimating the outputs with the limited number of data. In this study, a model was developed and coded in Python programming environment in order to predict cutting forces using ANN. The results showed that experimental cutting forces were estimated with a successful prediction rate of 0.99 with mean absolute percentage error and mean squared error of 1.85% and 13.1, respectively. Moreover, considering too limited experimental data, ANN provided acceptable results in a cost-and time-effective way. Copyright © The Author(s), 2020. Published by Cambridge University Press.Article Citation - WoS: 3Citation - Scopus: 4Investigation of the Combined Effects of Ultrasonic Vibration-Assisted Machining and Minimum Quantity Lubrication on Al7075-T6(John Wiley and Sons Ltd, 2024) Namlu, R.H.; Cetin, B.; Lotfi, B.; Kiliç, S.E.The aluminum alloy Al7075-T6 finds extensive application in the aviation and automotive industries, where machining plays a pivotal role. Emerging techniques such as Ultrasonic Vibration-Assisted Machining (UVAM) and Minimum Quantity Lubrication (MQL) hold promise for enhancing machining efficiency. In this study, the combined use of UVAM and MQL for slot milling of Al7075-T6 was investigated. The results demonstrate that UVAM reduced cutting forces by an average of 10.87% in MQL and 8.31% in Conventional Cutting Fluid (CCF) conditions when compared to Conventional Machining (CM). In addition, UVAM yielded significantly improved surface finishes, characterized by an average reduction in surface roughness of 41.86% in MQL and 32.11% in CCF conditions relative to CM. Furthermore, surfaces subjected to UVAM exhibited fewer instances of burn marks and tool-induced markings, reduced chip splashing, and more uniform surface integrity compared to those manufactured with CM. Lastly, chips generated through UVAM exhibited distinct characteristics, notably shorter length, curvier shape, and a distinctive half-turn morphology when compared with the irregular chips produced through CM. In conclusion, our findings underscore the potential of UVAM in synergy with MQL to augment the machining of Al7075-T6 alloy, thereby yielding superior-quality machined components with enhanced operational efficiency. © 2025 Elsevier B.V., All rights reserved.Article Citation - WoS: 12Citation - Scopus: 19An Ontology-Based Multi-Agent Virtual Enterprise System (omave): Part 1: Domain Modelling and Rule Management(Taylor & Francis Ltd, 2017) Sadigh, Bahram Lotfi; Unver, Hakki Ozgur; Nikghadam, Shahrzad; Dogdu, Erdogan; Ozbayoglu, A. Murat; Kilic, S. EnginNew advancements in computers and information technologies have yielded novel ideas to create more effective virtual collaboration platforms for multiple enterprises. Virtual enterprise (VE) is a collaboration model between multiple independent business partners in a value chain and is particularly suited to small and medium-sized enterprises (SMEs). The most challenging problem in implementing VE systems is ineffcient and inFLexible data storage and management techniques for VE systems. In this research, an ontology-based multi-agent virtual enterprise (OMAVE) system is proposed to help SMEs shift from the classical trend of manufacturing part pieces to producing high-value-added, high-tech, innovative products. OMAVE targets improvement in the FLexibility of VE business processes in order to enhance integration with available enterprise resource planning (ERP) systems. The architecture of OMAVE supports the requisite FLexibility and enhances the reusability of the data and knowledge created in a VE system. In this article, a detailed description of system features along with the rule-based reasoning and decision support capabilities of OMAVE system are presented. To test and verify the functionality and operation of this system, a sample product was manufactured using OMAVE applications and tools with the contribution of three SMEs.