Park, Jongee

Loading...

Profile URL

Name Variants

Jongee Park

P.,Jongee

P., Jongee

J.,Park

Park J.

Park, Jongee

Park,J.

J., Park

Park,Jongee

Jongee, Park

P.,Jongee

P., Jongee

J.,Park

Park J.

Park, Jongee

Park,J.

J., Park

Park,Jongee

Jongee, Park

Job Title

Profesör Doktor

Email Address

jongee.park@atilim.edu.tr

Main Affiliation

Metallurgical and Materials Engineering

Status

Website

ORCID ID

Scopus Author ID

Turkish CoHE Profile ID

Google Scholar ID

WoS Researcher ID

Sustainable Development Goals

2

ZERO HUNGER

0

Research Products

11

SUSTAINABLE CITIES AND COMMUNITIES

1

Research Products

14

LIFE BELOW WATER

0

Research Products

6

CLEAN WATER AND SANITATION

0

Research Products

1

NO POVERTY

0

Research Products

5

GENDER EQUALITY

0

Research Products

9

INDUSTRY, INNOVATION AND INFRASTRUCTURE

0

Research Products

16

PEACE, JUSTICE AND STRONG INSTITUTIONS

0

Research Products

17

PARTNERSHIPS FOR THE GOALS

0

Research Products

15

LIFE ON LAND

0

Research Products

10

REDUCED INEQUALITIES

0

Research Products

7

AFFORDABLE AND CLEAN ENERGY

12

Research Products

8

DECENT WORK AND ECONOMIC GROWTH

0

Research Products

4

QUALITY EDUCATION

0

Research Products

12

RESPONSIBLE CONSUMPTION AND PRODUCTION

0

Research Products

3

GOOD HEALTH AND WELL-BEING

2

Research Products

13

CLIMATE ACTION

0

Research Products

Documents

53

Citations

918

h-index

19

Documents

50

Citations

885

Scholarly Output

56

Articles

44

Views / Downloads

250/1108

Supervised MSc Theses

3

Supervised PhD Theses

0

WoS Citation Count

815

Scopus Citation Count

845

WoS h-index

19

Scopus h-index

19

Patents

0

Projects

1

WoS Citations per Publication

14.55

Scopus Citations per Publication

15.09

Open Access Source

6

Supervised Theses

3

Google Analytics Visitor Traffic

| Journal | Count |

|---|---|

| Ceramics International | 10 |

| Journal of Nanoscience and Nanotechnology | 3 |

| Applied Surface Science | 2 |

| 3rd International Conference on NANOCON -- SEP 21-23, 2011 -- Brno, CZECH REPUBLIC | 2 |

| Advanced Materials Research -- 2012 International Conference on Advances in Materials Science and Engineering, AMSE 2012 -- 9 December 2012 through 10 December 2012 -- Seoul -- 95488 | 2 |

Current Page: 1 / 7

Scopus Quartile Distribution

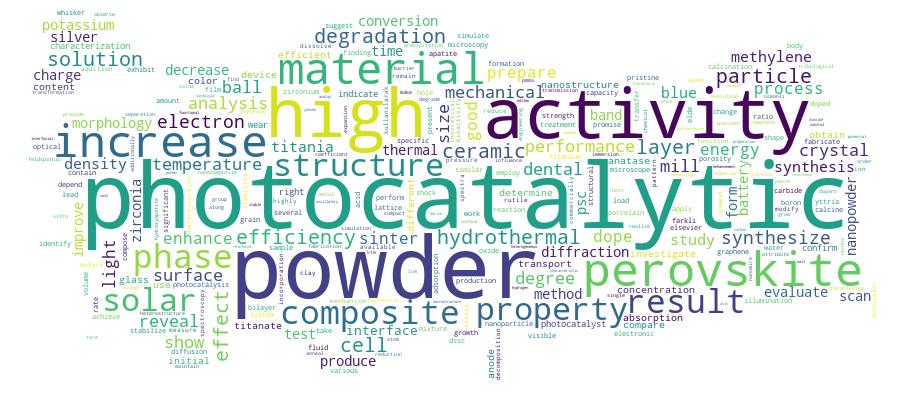

Competency Cloud

56 results

Scholarly Output Search Results

Now showing 1 - 10 of 56

Article Citation - WoS: 8Effect of H2o Ratio on Photocatalytic Activity of Sol-Gel Tio2 Powder(Ice Publishing, 2013) Agartan, Lutfi; Kapusuz, Derya; Park, Jongee; Ozturk, AbdullahEffect of water/tetraethyl orthotitanate molar ratio (R) on the formation and morphology of sol-gel-derived titania powder has been studied. Solutions for R of 3 and 5 have been prepared. Initial viscosity of the solutions and viscosity of the gels prepared by aging the solutions for some time were measured. Results revealed that lower gel viscosities lead to better crystallization of the aerogel. Aerogels were dried at 80 degrees C for 24 h and then calcined at 300 degrees C for 1 h to obtain titania powders. The structural and morphological analyses of the powders were performed using X-ray diffraction and scanning electron microscopic characterization techniques. Titania particles obtained after calcination composed of only anatase phase and were in the size range of 9-50 nm. The photocatalytic activity of the powders was evaluated in terms of the degradation of methylene blue (MB) solution under UV (ultraviolet) illumination. A diffuse reflectance spectroscopy was used for the band gap energy measurements. Results revealed that R had a profound effect on the particle morphology and photocatalytic activity of sol-gel-derived titania powders. The titania powders prepared from the solution for R of 5 degraded 99.47% of MB solution under UV illumination in 90 min.Article Citation - WoS: 44Citation - Scopus: 43Sol-Gel Synthesis and Photocatalytic Activity of B and Zr Co-Doped Tio2(Pergamon-elsevier Science Ltd, 2013) Kapusuz, Derya; Park, Jongee; Ozturk, AbdullahEffects of boron (B) and/or zirconium (Zr) doping on photocatalytic activity of sol-gel derived titania (TiO2) powders were investigated. A conventional, non-hydrous sol-gel technique was applied to synthesize the B, Zr doped/co-doped TiO2 powders. Doping was made at molar ratios of Ti/B=1 and Ti/Zr=10. Sol-gel derived xero-gels were calcined at 500 degrees C for 3 h. The crystal chemistry and the morphology of the undoped and B, Zr doped/co-doped TiO2 nanoparticles were investigated using X-ray diffractometer and scanning electron microscope. Nano-scale (9-46 nm) TiO2 crystallites were obtained after calcination. Doping and co-doping decreased the crystallite size. Photocatalytic activity was measured through the degradation of methylene blue (MB) under 1 h UV-irradiation using a UV-vis spectrophotometer. Results revealed that B doping into anatase caused the formation of oxygen vacancies, whereas Zr addition caused Ti substitution. Both B and Zr ions had a profound effect on the particle morphology and photocatalytic activity of TiO2. The photocatalytic activity of B and Zr doped TiO2 particles increased from 27% to 77% and 57%, respectively. The best activity (88.5%) was achieved by co-doping. (C) 2013 Elsevier Ltd. All rights reserved.Conference Object Citation - WoS: 1PRODUCTION OF SILVER LOADED PHOTOCATALYTIC TIO2 POWDERS BY BALL MILLING(Tanger Ltd, 2011) Aysin, Basak; Park, Jongee; Ozturk, AbdullahThe present study was undertaken to improve photocatalytic efficiency of TiO2 powder by silver doping and/or particle size reduction through mechanical ball milling. A planetary ball mill was employed to reduce the particle size of TiO2 powders to nanoscale and silver loading to TiO2 powders. Silver nitrate was used as silver source to obtain about 1% Ag load. Slurry taken from ball mill was separated by centrifugal separator into nano and micro sols. Separated nanosol was taken into the furnace to be dried at 103 degrees C and calcined at 400 degrees C for 1 hour to assist silver loading. X-Ray powder diffraction (XRD) was employed to identify the crystalline phases present in the powders produced. XRD results revealed that doped TiO2 powders were consisted of only anatase phase of TiO2. Changes in lattice parameters of TiO2 structure after doping were determined also by XRD. Scanning Electron Microscope (SEM) and particle size analyzer were used for examining the size reduction effect of ball milling process. Photocatalytic performance of the powders was evaluated by Methylene Orange (MO) test under UV light illumination using UV-Spectrophotometer.Article Citation - WoS: 29Citation - Scopus: 29A Newly Constructed Photoactive System, Fe(iii)-c/N-bi2< for Efficient Visible Light Photocatalysis(Elsevier Science Sa, 2018) Sudrajat, Hanggara; Park, Jongee; Hartuti, Sri; Park, Jongee; Park, Jongee; Metallurgical and Materials Engineering; Metallurgical and Materials EngineeringIn this study, two strategies are simultaneously applied for photocatalytic activity enhancement of Bi2O3. The first strategy is to increase the light absorption via simultaneous carbon and nitrogen doping. The second strategy is to increase the charge carrier separation via Fe grafting. Transmission electron microscopy observation reveals the presence of Fe nanoclusters resided on the Bi2O3 surface. Near edge Xray absorption fine structure (NEXAFS) analysis confirms the valence state of the Fe species to be +3, and their coordination to be octahedral. The C K-edge and N K-edge NEXAFS spectra furthermore confirm the incorporation of C and N species in the Bi2O3 structure. This newly constructed photocatalyst, denoted as Fe(III)-C/N-Bi2O3, shows appreciably enhanced photocatalytic performance for the decomposition of 2,4-dichlorophenol under visible light as compared to bare Bi2O3. (C) 2018 Elsevier B.V. All rights reserved.Article Citation - WoS: 48Citation - Scopus: 53Synthesis of Α-fe2o3< Heterogeneous Composites by the Sol-Gel Process and Their Photocatalytic Activity(Elsevier Science Sa, 2020) Bouziani, Asmae; Park, Jongee; Ozturk, Abdullahalpha-Fe2O3/TiO2 heterogeneous composites were synthesized by the sol-gel process to increase the photocatalytic activity of TiO2. The structural, morphological, and optical characteristics of the composites were determined by X-ray diffraction, scanning electron microscope, and UV-vis diffuse reflectance spectroscopy. Results revealed that the incorporation of alpha-Fe2O3 to TiO2 widened the visible light absorption ability of TiO2. It was realized that the calcination temperature plays a crucial role in morphology development hence photocatalytic activity of the alpha-Fe2O3/TiO2 heterogeneous composites. The photocatalytic activity of the composites calcined at various temperatures was evaluated for the degradation of Methylene Blue (MB) and Phenol (Ph) in aqueous medium under UV and sun-like illuminations. The alpha-Fe2O3-TiO2 composites exhibits superior photocatalytic efficiency to degrade both MB and Ph as compared to both pristine TiO2 and pristine alpha-Fe2O3 under sun-like illumination. The alpha-Fe2O3/TiO2 composite degraded approximately 90 % of MB and 50 % of Ph in 180 min sun-like illumination. Improvement in photocatalytic activity is attributed to the separation of photogenerated electron/hole pairs through the interaction of alpha-Fe(2)O(3 )and TiO2.Conference Object Citation - Scopus: 1Production of Highly Efficient Photocatalytic Tio2 Powders by Mechanical Ball Milling(2013) Oztas,T.; Park,J.; Ozturk,A.Highly efficient photocatalytic TiO2 powders were prepared using a conventional ball mill with various milling times of 0, 12, 24 and 48 h. The photocatalytic activity of the prepared TiO2 powders was evaluated using the decomposition rate obtained by methylene blue (MB) solution and acetic acid gas under UV light irritation. After 24 h milling, the particle size decreased from 555 nm to 122 nm without changing any of the crystal structure. The photocatalytic TiO2 powders prepared by 24 h milling decomposed 94% of the methylene blue solution while the nonmilled TiO2 powders provided only 61% decomposition. After the removal of acetic acid gas, it took 1.5 h for the 24h-milled powders to decompose 100%, while the non-milled TiO2 showed 73% decomposition with same UV illumination duration. © (2013) Trans Tech Publications, Switzerland.Conference Object Citation - Scopus: 2Synthesis of Tio2 Nanostructures Via Hydrothermal Method(American Ceramic Society, 2015) Bilgin,N.; Agartan,L.; Park,J.; Ozturk,A.Titania (TiO2) nanostructures were produced via hydrothermal method using amorphous TiO2 powders synthesized by the sol-gel precipitation process. The hydrothermal system was isolated from the environment and hydrothermal reactions were allowed to execute at 130 °C for 36 h at autogeneous pressure, and at a stirring rate of 250 rpm. Scanning electron microscopy (SEM) analysis revealed that TiO2 nanofibers formed instead of nanotubes upon utilization of amorphous TiO2 precursor. After hydrothermal synthesis, the powders were acid treated by HCl several times. X-ray diffraction (XRD) analysis identified that the synthesized powders were Na-titanate and remained Na-titanate even after subjecting to acidic treatments several times. The photocatalytic performance of the powders was evaluated by degradation of methylene blue (MB) solution in UV illumination. Results were compared with nanotubes which were synthesized previously using P25 commercial titania powder and have shown that TiO2 in tubular structure offers better photocatalytic performance for the degradation of MB solution under UV illumination as compared to fiber-like structure. Copyright © 2015 by The American Ceramic Society. All rights reserved.Article Citation - WoS: 57Citation - Scopus: 67Mechanical Properties of B4c-sic Composites Fabricated by Hot-Press Sintering(Elsevier Sci Ltd, 2020) So, Sung Min; Choi, Woo Hyuk; Kim, Kyoung Hun; Park, Joo Seok; Kim, Min Suk; Park, Jongee; Kim, Hyung SunWe fabricated boron carbide-silicon carbide (B4C-SiC) composites by hot-press sintering without additives and evaluated the crystal phase, relative density, microstructure, and mechanical properties of the sintered body. When B4C and SiC were uniformly dispersed in the composite, crystal growth was inhibited, and a sintered body with a fine and uniform microstructure, with improved mechanical properties, was fabricated. The relative density of B4C-SiC composites sintered at temperatures lower than 2000 degrees C and 40 MPa of pressure exceeded 99.8%, and the bending strength and Vickers hardness at B4C 50 wt% were 645 MPa and 30.6 GPa, respectively.Article Citation - WoS: 32Citation - Scopus: 28Photocatalytic activity of hydroxyapatite-precipitated potassium titanate whiskers(Elsevier Science Sa, 2010) Park, JongeePhotocatalytic properties of hydroxyapatite (HAP)-precipitated multifunctional potassium titanate (KT) whiskers were investigated in terms of the decomposition of methylene blue (MB) in aqueous solution under UV irradiation. Hydroxyapatite was formed on the surface of KT whiskers through a biomimetic process in simulated body fluid (SBF). The SBF used in this investigation had concentrations of calcium and phosphate ions 10 times greater than those of human plasma. Results revealed that hydroxyapatite precipitation enhanced the photocatalytic activity of the KT whiskers. In the case of unreacted KT whisker, complete degradation of methylene blue took 5.5 h, on the other hand degradation time decreased to 3.5 h when the whisker was precipitated with hydroxyapatite. (C) 2009 Elsevier B.V. All rights reserved.Article Citation - WoS: 12Citation - Scopus: 11Enhanced Bioactivity and Low Temperature Degradation Resistance of Yttria Stabilized Zirconia/Clay Composites for Dental Applications(Elsevier Sci Ltd, 2022) Tufan, Yigithan; Park, Jongee; Ozturk, Abdullah; Ercan, BaturYttria stabilized zirconia (YSZ)/clay composites were produced to improve osseointegration and undesired tetragonal-to-monoclinic phase transformation (low temperature degradation, LTD) of YSZ ceramics so that long-term clinical success of YSZ implants is achieved. Various amounts (0.5,1,2, and 4 wt%) of clay was incorporated to YSZ. Predetermined amounts of clay and YSZ were mixed and pressed uniaxially at 15 MPa into compacts that were subsequently pressureless sintered at 1450 degrees C. Density, compressive strength, hardness and indentation crack resistance of 4 wt% clay incorporated YSZ/clay composite were 5.77 +/- 0.01 g/cm3, 1188 +/- 121 MPa, 1223 +/- 9 HV, and 4.4 +/- 0.1 MPa root m, respectively. Additionally, biological properties of YSZ/clay composites were assessed in vitro using bone cells. Incorporation of 4 wt% clay significantly enhanced bone cell prolifer-ation, spreading, and functions. Moreover, a significant increase in the LTD resistance of YSZ was achieved upon 4 wt% clay incorporation. The findings collectively suggest that YSZ/clay composites have a potential to be used as an alternative material for dental applications.