Durkaya, Göksel

Loading...

Profile URL

Name Variants

Durkaya, G.

Durkaya, Goksel

Durkaya, Göksel

G., Durkaya

D., Goksel

D.,Göksel

D.,Goksel

Göksel, Durkaya

G.,Durkaya

Goksel, Durkaya

Durkaya,G.

Durkaya, Goksel

Durkaya, Göksel

G., Durkaya

D., Goksel

D.,Göksel

D.,Goksel

Göksel, Durkaya

G.,Durkaya

Goksel, Durkaya

Durkaya,G.

Job Title

Doktor Öğretim Üyesi

Email Address

goksel.durkaya@atilim.edu.tr

Main Affiliation

Department of Metallurgical and Materials Engineering

Status

Former Staff

Website

ORCID ID

Scopus Author ID

Turkish CoHE Profile ID

Google Scholar ID

WoS Researcher ID

Sustainable Development Goals

SDG data is not available

This researcher does not have a Scopus ID.

This researcher does not have a WoS ID.

Scholarly Output

8

Articles

3

Views / Downloads

26/114

Supervised MSc Theses

1

Supervised PhD Theses

0

WoS Citation Count

10

Scopus Citation Count

15

WoS h-index

1

Scopus h-index

1

Patents

0

Projects

0

WoS Citations per Publication

1.25

Scopus Citations per Publication

1.88

Open Access Source

4

Supervised Theses

1

Google Analytics Visitor Traffic

| Journal | Count |

|---|---|

| 8th International Advances in Applied Physics and Materials Science Congress and Exhibition (APMAS) -- APR 24-30, 2018 -- Fethiye, TURKEY | 3 |

| 20th International Conference on Miniaturized Systems for Chemistry and Life Sciences, MicroTAS 2016 -- 20th International Conference on Miniaturized Systems for Chemistry and Life Sciences, MicroTAS 2016 -- 9 October 2016 through 13 October 2016 -- Dublin -- 126047 | 1 |

| BOR DERGİSİ | 1 |

| Ceramics International | 1 |

| International Journal of Mechatronics and Manufacturing Systems | 1 |

Current Page: 1 / 1

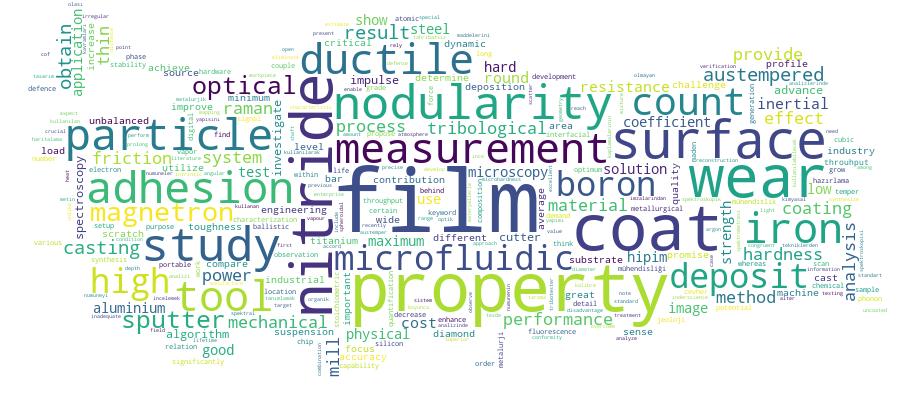

Competency Cloud