This item is non-discoverable

Billur, Eren

Loading...

Profile URL

Name Variants

Billur, E.

Eren, Billur

E., Billur

E.,Billur

B.,Eren

B., Eren

Billur, Eren

Billur,E.

Eren, Billur

E., Billur

E.,Billur

B.,Eren

B., Eren

Billur, Eren

Billur,E.

Job Title

Doktor Öğretim Üyesi

Email Address

eren.billur@atilim.edu.tr

Main Affiliation

Automotive Engineering

Status

Former Staff

Website

ORCID ID

Scopus Author ID

Turkish CoHE Profile ID

Google Scholar ID

WoS Researcher ID

Sustainable Development Goals

3

GOOD HEALTH AND WELL-BEING

2

Research Products

7

AFFORDABLE AND CLEAN ENERGY

1

Research Products

9

INDUSTRY, INNOVATION AND INFRASTRUCTURE

1

Research Products

This researcher does not have a Scopus ID.

This researcher does not have a WoS ID.

Scholarly Output

9

Articles

4

Views / Downloads

29/75

Supervised MSc Theses

1

Supervised PhD Theses

0

WoS Citation Count

40

Scopus Citation Count

43

WoS h-index

3

Scopus h-index

3

Patents

0

Projects

0

WoS Citations per Publication

4.44

Scopus Citations per Publication

4.78

Open Access Source

3

Supervised Theses

1

Google Analytics Visitor Traffic

| Journal | Count |

|---|---|

| 28th International Conference on Metallurgy and Materials (METAL) -- MAY 22-24, 2019 -- Brno, CZECH REPUBLIC | 1 |

| 5th International Conference on Hot Sheet Metal Forming of High-Performance Steel (CHS2 2015) -- MAY 31-JUN 03, 2015 -- Toronto, CANADA | 1 |

| Hittite Journal of Science and Engineering | 1 |

| International Conference on the Technology of Plasticity (ICTP) -- SEP 17-22, 2017 -- Cambridge, ENGLAND | 1 |

| International Journal of Hydrogen Energy | 1 |

Current Page: 1 / 2

Scopus Quartile Distribution

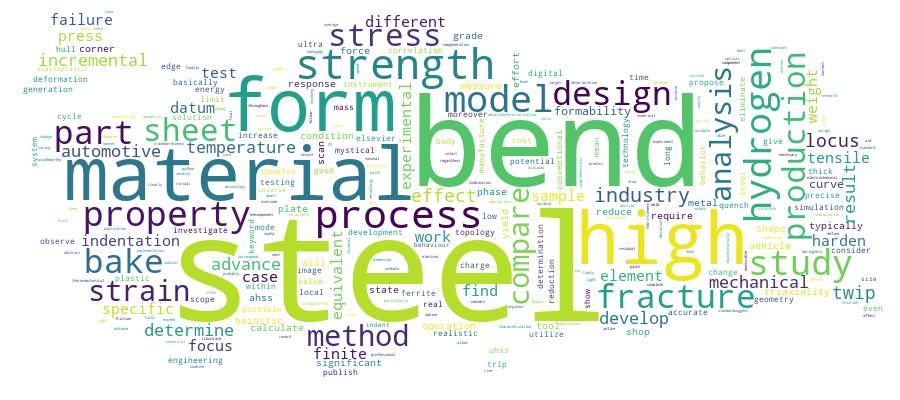

Competency Cloud

9 results

Scholarly Output Search Results

Now showing 1 - 9 of 9

Book Part Citation - WoS: 19Citation - Scopus: 17Article Citation - WoS: 13Citation - Scopus: 17Effect of hydrogen on fracture locus of Fe-16Mn-0.6C-2.15Al TWIP steel(Pergamon-elsevier Science Ltd, 2020) Bal, Burak; Cetin, Baris; Bayram, Ferdi Caner; Billur, ErenEffect of hydrogen on the mechanical response and fracture locus of commercial TWIP steel was investigated comprehensively by tensile testing TWIP steel samples at room temperature and quasi-static regime. 5 different sample geometries were utilized to ensure different specific stress states and a digital image correlation (DIC) system was used during tensile tests. Electrochemical charging method was utilized for hydrogen charging and microstructural characterizations were carried out by scanning electron microscope. Stress triaxiality factors were calculated throughout the plastic deformation via finite element analysis (FEA) based simulations and average values were calculated at the most critical node. A specific Python script was developed to determine the equivalent fracture strain. Based on the experimental and numerical results, the relation between the equivalent fracture strain and stress triaxiality was determined and the effect of hydrogen on the corresponding fracture locus was quantified. The deterioration in the mechanical response due to hydrogen was observed regardless of the sample geometry and hydrogen changed the fracture mode from ductile to brittle. Moreover, hydrogen affected the fracture locus of TWIP steel by lowering the equivalent failure strains at given stress triaxiality levels. In this study, a modified Johnson-Cook failure mode was proposed and effect of hydrogen on damage constants were quantified. (C) 2020 Hydrogen Energy Publications LLC. Published by Elsevier Ltd. All rights reserved.Article Citation - Scopus: 2Temperature Effects in Deep Drawing of Advanced High Strengthsteels(MIM RESEARCH GROUP, 2021) Akcan, Kadir; Billur, Eren; Saraç, H. İbrahimAs advanced high strength steels (AHSS) find more use in automotive industry to meet crashworthiness and light weighting targets, concurrently. AHSS typically have higher strength, but lower formability; often limiting a part’s dimensions and geometric complexity. Several studies have clearly shown that, in sheet metal forming, significant portion of the work done to overcome friction and to plastically deform a sheet is converted into heat. In this study, a thermomechanical finite element model has been developed to calculate the temperature rise in forming DP800 (AHSS). The model was validated with experiments from literature. A multi-cycle model is developed to find out possible problems due to tool heating. The process and material are selected to speed up the heating. Under different realistic press conditions, failures are observed after 20 to 80 hits.Conference Object Citation - WoS: 3From Part Design To Part Production - Virtual Hot Forming Engineering Illustrated - Focus Material Modelling(verlag Wissenschaftliche Scripten, 2015) Billur, Eren; Porzner, Harald; Lorenz, D.; Holecek, Martin; Vrojlik, M.; Hoss, M.; Skrikerud, MartinIn a press hardening process, significant efforts are necessary to model material behavior and combinations of material in one part, patch work, and die spotting. In this paper, a focus will be put on accurate modeling of material and process, being able to complete the die and process design in a timely manner A new material model has been developed that allows measuring and modelling material behavior along measurable phase paths. The reward of precise material and process modelling is a realistic determination of the deviation of the formed shape from the nominal part shape, accurate quenching time determination, correct material properties and residual stresses at the end of the process, and significant time savings in the try-out period.Article Citation - WoS: 2Citation - Scopus: 3Development of New Vehicle Safety Structures by Using Third Generation Steels(Sae int, 2022) Erzincanlioglu, Samet; Aydiner, Tamer; Aras, Firat; Celik, Hafize; Billur, Eren; Karabulut, Semih; Gumus, Iskender OnderResearch and development efforts in the automotive industry have been long focused on crashworthy, durable vehicles with the lowest mass possible as higher mass requires more energy and, thus, causes more CO2 emissions. One way of approaching these objectives is to reduce the total vehicle weight by using higher strength-to-weight ratio materials, such as Advanced High-Strength Steels (AHSS). Typically, as the steel gets stronger, its formability is reduced. The steel industry has been long developing (so-called) third-generation (Gen3) AHSS for the automotive industry. These grades offer higher formability compared to first-generation (Gent) and cost less compared to the second-generation (Gen2) AHSS. Transformation Induced Plasticity (TRIP)-aided Bainitic Ferrite (TBF) and Quenching and Partitioning (Q&P) steel families are considered to be the Gen3 AHSS. These grades can be cold-formed to more complex shapes, compared with the Geni Dual Phase (DP) and TRIP steels at equivalent strength levels. In this article, new single-piece A- and B-pillar reinforcements were designed using a Gen3 AHSS, TBF980. Spot-welding operations were eliminated due to part consolidation with the more formable steel. These parts will be the first structural automotive parts which were manufactured with cold-forming technology using TBF steels with a sstrength level close to 1 GPa or even more. Weight and cost reductions were realized by the new design while improving the crash performance.Master Thesis Yüksek Mukavemetli Kalın Çelik Plakaların Adımsal Bükülmesine Yönelik Yeni Bir Proses Tasarımı ve Uygulaması(2018) Çetin, Barış; Billur, Eren; Baranoğlu, BesimZırhlı muharebe aracı üretiminin önemli bir alt işlemi olan gövde imalatında ultra yüksek mukavemetli çeliklerin (UHSS) bükülmesi önemli bir üretim aşamasıdır. Bu bükme işlemi genellikle havada bükme koşulunda (air bending) yüksek tonajlı abkant preslerde gerçekleştirilmektedir. Gövde üretiminde kullanılan çelikler, 1250 MPa gibi geleneksel yumuşak çeliklere kıyasla çok yüksek kopma mukavemetlerine sahip olabilmektedir. Bu mukavemet seviyelerinin doğal bir sonucu olarak yüksek bükme kuvvetlerine ihtiyaç doğmaktadır. Diğer yandan, yeni nesil bir imalat yöntemi olarak adlandırılabilecek olan, plastik şekil değiştirmenin adımsal olarak uygulanmasına dayanan adımsal sac şekillendirme yöntemi, son dönemlerde metal şekillendirme endüstrisinde kullanılmaktadır. Bu yeni teknik, şekillendirilebilirliğin arttırılması, karmaşık kalıp tasarımlarına olan gerekliliğin ortadan kaldırılması ve şekillendirme kuvvetlerinin önemli ölçüde azaltılmasında bazı avantajlara sahiptir. Bu tez çalışmasında temel olarak adımsal şekillendirme prosesinin büküm kuvvetinin azaltılması üzerindeki potansiyeli araştırılmıştır. Tezin kapsamı içerisinde yeni bir adımsal bükme prosesi önerilmiş, proses sonlu elemanlar yöntemi ile benzetilmiş ve deneysel olarak doğrulanmıştır. Benzetimler ve deneysel çalışmalar sonucunda elde edilen datalar üzerinde yapılan çalışmalar sayesinde bazı proses parametreleri de optimize edilmiştir. Bununla birlikte, adımsal bükme işlemi, konvansiyonel havada bükme işlemi de ile karşılaştırılmıştır.Article Mechanical Properties of Trip Aided Bainitic Ferrite (tbf) Steels in Production and Service Conditions(2018) Billur, Eren; Karabulut, Semih; Yılmaz, İmren Öztürk; Erzincanoğlu, Samet; Çelik, Hafize; Altınok, Evren; Başer, TanyaIn the automotive industry, one of the most common methods to reduce the weight of the body components is to downgage the sheets using higher strength steels. In the design phase, engineers typically use the material properties of the incoming material, suchas the yield strength and the elongation. For forming analyses, however, more detailedcharacterization is required (flow curves, anisotropy, forming limit curves, etc.). Once thecomponents are formed in the press shop, the yield strength increases due to work (strain)hardening. The parts are then welded in the body shop, and the body-in-white goes to thepaint shop where it is baked to cure the paint. Most steels’ yield strength changes duringthis paint bake cycle, which determines its final properties in service. Bake hardening (andin some cases, bake softening) is measured by Bake Hardening Index (BHI) as defined byEN 10325-2006. The standard dictates relatively low pre-strain (2%) and baking temperature (170°C). In real production conditions however, higher strains are achieved andbaking temperatures may exceed 170°C to shorten the baking time. In this study, a newgeneration Advanced High Strength Steel (AHSS) grade TBF 1050 was characterized formetal forming purposes and its bake hardening response was studied both as the standardsuggests and as the real production cycle dictates.Conference Object Predicting the Topology of the Bending Corner in Bending of Ultra High Strength Steels Through Finite Element Analysis(Tanger Ltd, 2019) Cetin, Baris; Billur, Eren; Baranoglu, Besim; Toptas, Ugur; Alic, Ozgur; Manufacturing Engineering; Automotive EngineeringIn bending of plates, unlike the case of sheet metal forming, a 3-D stress state is valid. Moreover, apart from the some very specific cases, the plane strain assumption is not appropriate either. Therefore; bending of thick ultra-high strength steel (UHSS) plates is a deformation process where 3-D stress and strain states exist in general. This study basically focuses on the prediction of the bending corner topology with non-linear finite element analysis method, since the laser-cut edges of the UHSS are particularly prone to edge cracking during bending operation. Within the scope of this study, an experimental set-up is designed which consists of bending tools and a servo mechanical press. The samples were bent by means of this set-up in an air-bending operation up to 90 degrees. This experimental work was followed by optical scanning measurements. And finally, the FEA results and the scanning data were compared in 3-D space. The results showed good correlation. As a future study, the 3-D strain field of the bending corner will be tried to be measured by a professional digital image correlation (DIC) system which could probably give more precise data when combined with the data from FEA.Conference Object Citation - WoS: 3Citation - Scopus: 4A Potential Solution To Mystical Materials in Indentation Test(Elsevier Science Bv, 2017) Billur, E.; Cetin, B.; Music, O.; Simsir, C.; Davut, K.Various methods have been designed to determine the elasto-plastic properties of metals. Instrumented indentation test (IIT) is considered to be a good candidate to determine local properties after manufacturing operations. In order to acquire elastoplastic properties from IIT, either dimensional analysis or inverse analysis of the force-displacement curve is performed. However, the major drawback of those methods is the uniqueness of the solution. Some materials may exhibit almost identical force-depth curves, although they have different elastoplastic properties. Those materials are referred as "mystical materials". In this contribution, topological features of the indentation surfaces, i.e. indent size, pile-up and sink-in behaviour, are investigated to find a differentiating property. According to the results, indent size, pile-up and sink-in behaviour may help to find the unique solution to the inverse problem. (C) 2017 The Authors. Published by Elsevier Ltd. Peer-review under responsibility of the scientific committee of the International Conference on the Technology of Plasticity.