Tirkeş, Seha

Loading...

Profile URL

Name Variants

Tirkes, Seha

S.,Tirkes

T., Seha

T.,Seha

Tirkeş, Seha

Tirkes,Seha

Seha Tirkeş

S., Tirkes

S.,Tirkeş

Seha, Tirkeş

Seha, Tirkes

Tirkes S.

Tirkeş,S.

Tirkes,S.

Tirkeş S.

S., Tirkeş

S.,Tirkes

T., Seha

T.,Seha

Tirkeş, Seha

Tirkes,Seha

Seha Tirkeş

S., Tirkes

S.,Tirkeş

Seha, Tirkeş

Seha, Tirkes

Tirkes S.

Tirkeş,S.

Tirkes,S.

Tirkeş S.

S., Tirkeş

Job Title

Profesör Doktor

Email Address

seha.tirkes@atilim.edu.tr

Main Affiliation

Chemical Engineering

Status

Website

ORCID ID

Scopus Author ID

Turkish CoHE Profile ID

Google Scholar ID

WoS Researcher ID

Sustainable Development Goals

3

GOOD HEALTH AND WELL-BEING

1

Research Products

6

CLEAN WATER AND SANITATION

1

Research Products

9

INDUSTRY, INNOVATION AND INFRASTRUCTURE

2

Research Products

11

SUSTAINABLE CITIES AND COMMUNITIES

1

Research Products

14

LIFE BELOW WATER

1

Research Products

This researcher does not have a Scopus ID.

This researcher does not have a WoS ID.

Scholarly Output

39

Articles

25

Views / Downloads

158/1884

Supervised MSc Theses

12

Supervised PhD Theses

1

WoS Citation Count

422

Scopus Citation Count

457

WoS h-index

14

Scopus h-index

15

Patents

0

Projects

0

WoS Citations per Publication

10.82

Scopus Citations per Publication

11.72

Open Access Source

6

Supervised Theses

13

Google Analytics Visitor Traffic

| Journal | Count |

|---|---|

| Electrochimica Acta | 2 |

| Materials Research Express | 2 |

| Journal of Electroanalytical Chemistry | 2 |

| Clay Minerals | 1 |

| International Conference on Materials and Nanomaterials (MNs) -- JUL 17-19, 2019 -- Paris, FRANCE | 1 |

Current Page: 1 / 5

Scopus Quartile Distribution

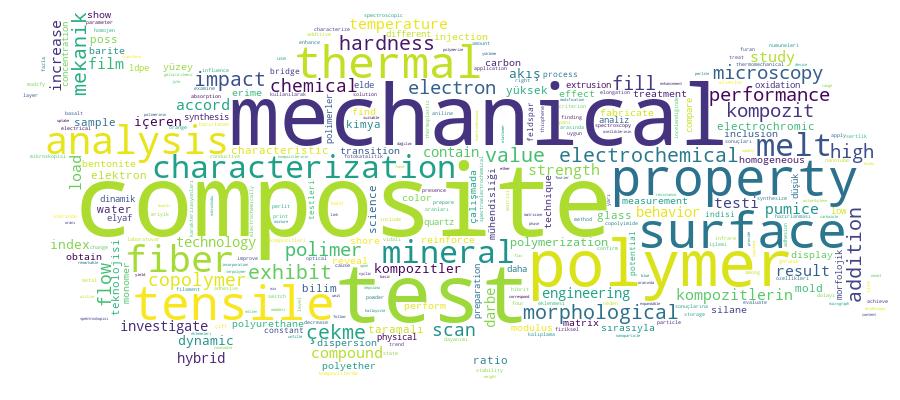

Competency Cloud

39 results

Scholarly Output Search Results

Now showing 1 - 10 of 39

Master Thesis Barit ve Bentonit Eklenmiş Düşük Yoğunluklu Polietilen Kompozitlerinin Mekanik ve Fiziksel Karakterizasyonu(2018) Elkawash, Hesham Mohammed S; Tirkeş, Seha; Hacıoğlu, FıratBu tez çalışmasında, bentonit (BNT) ve barit (BRT) olarak iki farklı dolgu maddesi düşük yoğunluklu polietilen (LDPE) içerisine ekstrüzyon işlemi ile eklenmiştir. BRT and BNT yüzeylerine, polimer matrisi ile uyumlarını artırmak amacıyla silanlama işlemi uygulanmıştır. Dolguların yüzey karakteristikleri infrared spektroskopisi (FTIR) ile incelenmiştir. LDPE bazlı kompozitler, her bir dolgu maddesi için %10 sabit konsantrasyonunda hazırlanmıştır. Test numuneleri enjeksiyonlu kalıplama kullanılarak hazırlanmıştır. Eklentisiz LDPE ve kompozitlerinin mekanik, ısısal-mekanik, eriyik-akış ve morfolojik karakterizasyonları sırasıyla, çekme ve darbe testleri, dinamik mekanik analiz (DMA), eriyik akış indisi (MFI) testi ve taramalı elektron mikroskopisi (SEM) tekniği ile gerçekleştirilmiştir. Test sonuçları göstermiştir ki, yüzey işlemleri, BNT ve BRT'nin LDPE matrisine işlem uygulanmamış olanlara kıyasla daha iyi yapışmasından dolayı kompozitlerin son özelliklerini arttırmıştır. LDPE'nin çekme ve darbe dayanımları, depolama modülü ve camsı geçiş sıcaklığı, silanlanmış dolgular ile yükselmiştir. MFI testinden çıkarım yapılmıştır ki, BRT ve BNT eklemeleri, LDPE'nin eriyik akış hızında belirgin bir değişim ile sonuçlanmamıştır. Kompozitlerin SEM analizine göre, silanlama uygulanmış BNT ve BRT içeren örnekler homojen dağılım sergilerken işlenmemiş BNT ve BRT takviyeli kompozitlerde bu dolguların polimer matrisine zayıf yapışmalarından ötürü bağ açılmaları gözlenmiştir.Article Citation - WoS: 8Citation - Scopus: 9Contribution of Surface Silanization Process on Mechanical Characteristics of Tpu-Based Composites Involving Feldspar and Quartz Minerals(Wiley, 2023) Bouzmane, Hajar; Tirkes, Suha; Yilmaz, Volkan Murat; Tayfun, Umit; Tirkes, SehaIn this study, quartz and feldspar powders were surface treated using a silane coupling agent to achieve a more compatible mineral surface with the polymer matrix. Details of surface characteristics of minerals were examined by energy-dissipative X-ray spectroscopy, contact angle measurements, and infrared spectroscopy. Thermoplastic polyurethane-TPU was compounded with minerals using the melt-blending technique. Mechanical, thermo-mechanical, melt-flow, and morphological characterizations of TPU and relevant composites were performed by utilizing tensile and Shore hardness tests, dynamic mechanical analysis (DMA), melt flow index (MFI) measurements, and scanning electron microscopy (SEM), respectively. Water repellency of TPU and composites were also evaluated experimentally. Effects of surface treatments were discussed by comparing the results of composites filled with pristine and modified minerals. Results revealed that enrichment of quartz and feldspar surfaces confer mechanical and thermo-mechanical performance of composites. Mineral inclusions caused no drastic changes to the MFI parameter of TPU. The silane layer on the mineral surface displayed a barrier effect to water uptake of composites. Homogeneous dispersion and improved interfacial adhesion of mineral particles to the TPU phase were confirmed with help of SEM observations. Quartz exhibited slightly higher performance thanks to its silica-rich composition. The findings of this research exhibited the considerable influence of the silane layer on the mineral surface on the mechanical performance of TPU-based composites.Article Citation - WoS: 30Citation - Scopus: 31A New Low-Voltage Polymeric Electrochromic(Elsevier Sci Ltd, 2010) Pamuk, Melek; Tirkes, Seha; Cihaner, Atilla; Algi, FatihDesign, synthesis, and properties of a novel donor-acceptor-donor type low-voltage-driven green polymeric electrochrome, P1, which is based on 8-(2,3-dihydrothieno[3,4-b][1,4]dioxin-5-yl)-11-(2,3-dihydrothieno[3,4-b][l,4]dioxin-7-yl)acenaphtho[1,2-b]quinoxaline (1) are highlighted. It is noted that P1 has an ambipolar (n- and p-doping processes) character in 0.1 M tetrabutylammonium hexafluorophosphate/dichloromethame solution and switches to a transmissive blue state upon oxidation. Furthermore, this new polymeric electrochromic candidate exhibits high redox stability, high coloration efficiency and/or contrast ratio, high percent transmittance (%T) and low response time (1.0 s) with a band gap of 1.10 eV-1.25 eV. (C) 2009 Elsevier Ltd. All rights reserved.Article Polilaktid Esaslı Biyobozunur Kompozitlerde Doğal Bir Katkı Maddesi Olarak Genişletilmiş Perlit Mineralinin Kullanımı(2024) Aksoy, Erkan; Tirkeş, Süha; Tayfun, Ümit; Tirkeş, SehaPolilaktit (PLA), tıptan paketlemeye kadar çeşitli uygulamalarda kullanılan, doğal kaynaklardan elde edilen ve biyolojik olarak parçalanabilen bir polimerdir. Bu çalışmada, biyokompozitler, doğal bir dolgu malzemesi olan perlit mineralinin (PER) biyolojik olarak parçalanabilen bir PLA matrisi ile %2.5, %5, %10 ve %15'lik ekleme oranlarında harmanlanarak hazırlanmıştır. Geliştirilen kompozitlerin işlenme, mekanik, erime akışı ve morfolojik özelliklerini belirlemek için kompozit numuneler üzerinde karıştırma kuvveti ölçümleri, çekme, Shore sertliği, darbe testleri, erime akış indisleri (MFI) ve taramalı elektron mikroskobu (SEM) değerlendirmeleri yapılmıştır. Çekme testi verileri incelendiğinde, perlit yüklemeleri ile çekme mukavemeti ve % uzama parametrelerinde ufak düşüşler görülmüştür. Perlit tozunun dahil edilmesi, PLA'nın darbe dayanımı değerini önemli ölçüde azaltmıştır. Yüksek miktarda PER içeren kompozitler, yüksek sertlik değerleri göstermiştir. MFI sonuçları analiz edildiğinde, PER ilavesinin PLA polimerinin erime akış özelliklerini arttırdığı bulunmuştur. Düşük PER miktarlarında, SEM mikrografları, PER partiküllerinin PLA fazında homojen bir şekilde dağıldığını ortaya çıkarmıştır. Kompozit morfolojisindeki partikül homojenliği, kompozitlerdeki PER yükleme oranı arttıkça bozulmuştur. Genel sonuçlara göre kompozitler arasında en yüksek performans %2,5 PER içeren numunede elde edilmiş ve bu numunenin PLA esaslı biyokompozit malzeme amaçlı uygulamalar için en uygun seçenek olduğu değerlendirilmiştir.Article Citation - WoS: 14Citation - Scopus: 12Electrochemical Synthesis of New Conjugated Polymers Based on Carbazole and Furan Units(Elsevier Science Sa, 2015) Oguzturk, H. Esra; Tirkes, Seha; Onal, Ahmet M.In this study, synthesis of four new monomers; 3,6-di(2-furyl)-9H-carbazole (M1), 3,6-di(2-furyl)-9-ethyl-carbazole (M2), 2,7-di(2-furyl)-9-H-carbazole (M3), 2,7-di(2-furyl)-9-(tridecan-7-yl)-9H-carbazole (M4), was achieved via Stifle cross-coupling reaction. The monomers were electrochemically polymerized, via repetitive cycling in acetonitrile-tetrabutylammonium hexafluorophosphate electrolytic medium. Optical and electrochemical properties of the monomers and their corresponding polymers were investigated and it was found that optical properties show slight variations depending on the connectivity between the carbazole and furan moieties. However, all the monomers synthesized in this work exhibited an irreversible oxidation peak at around 1.0 V. Electrochemically obtained polymer films, on the other hand, exhibited quasi-reversible redox behavior due to doping/dedoping of the polymers which was accompanied by a reversible electrochromic behavior. Their band gap values (E-g) were elucidated utilizing spectroelectrochemical data and it was found that polymers obtained from 2,7-substituted carbazole derivatives have slightly lower band gap values. Furthermore, scanning electron micrographs were used for morphological examinations. (C) 2015 Elsevier B.V. All rights reserved.Article Citation - WoS: 64Citation - Scopus: 73Production and Characterization of Poly (lactic Acid)-Based Biocomposites Filled With Basalt Fiber and Flax Fiber Hybrid(Sage Publications Ltd, 2020) Eselini, Najah; Tirkes, Seha; Akar, Alinda Oyku; Tayfun, UmitPoly (lactic acid) (PLA)-based biocomposites containing flax fiber (FF) and basalt fiber (BF) both separately and together were prepared by melt blending method at the total constant ratio of 30 wt%. Mechanical properties, thermo-mechanical characteristics, thermal stability, flow behaviors, water uptake, and morphology of composites were investigated by tensile, hardness and impact tests, dynamic mechanical analysis (DMA), thermal gravimetric analysis, melt flow index (MFI) test, water absorption, and scanning electron microscopy, respectively. Mechanical test results show that tensile strength, elongation, elastic modulus, and impact strength are extended up to higher values with increase in BF content in hybrid composites. Conversely, the presence of FF displays a negative effect in which these values drop down drastically as the FF concentration increases. On the other hand, slightly higher hardness values are obtained by the addition of FF at higher loadings. DMA analysis reveals that BF inclusion leads glass transition temperature of PLA to one point higher, but hybrid and FF containing composites shift that temperature to lower values. Storage moduli of composites are enhanced with the increase in BF concentration and remarkable decreases are observed for FF-filled composites. Hybrid composites exhibit average MFI values between PLA/FF and PLA/BF composites.Master Thesis Akrilonitril-bütadien-stiren Barit Kompozitlerinin Mekanik ve Termal Özellikleri(2017) Madkour, Salma Alı; Tirkeş, Seha; Tayfun, ÜmitGeniş uygulama alanlarına sahip olması nedeni ile akrilonitril-bütadien-stiren polimeri ile ilgili gerek mekanik gerek ise termal vb. özelliklerini geliştirmek adına çalışmalar halen devam etmekte. Yürütülen bu çalışmada akrilonitril-bütadien-stiren polimerine barit karıştırılarak kompozitler hazırlanmıştır. Hazırlıma sürecinde çift vidalı (aynı yönde dönen) mikro-karıştırıcı ve laboratuvar tipi enjeksiyon cihazı kullanılmıştır. Kompozitler hazırlanırken baritin kütlece oranları %5, %10, %15 ve %20 olarak seçilmiştir. Üretilen kompoiztler uygun test metotları ile karakterize edilmiştir. Bu testler çekme testi, darbe testi, dinamik mekanik analiz, erime akış indisi ve taramalı elektron mikroskobudur.Master Thesis Asidik Pomza Tozu ile Katkılandırılmış Akrilonitril-bütadien-stiren Kompozitlerinin Hazırlanması ve Karakterizasyonu(2017) Alaq, Sanaa Alı E.; Tirkeş, Seha; Tayfun, ÜmitAkrilonitril-bütadien-stiren polimerinin fiziksel, termal ve reolojik özelliklerinin geliştirilmesi çalışmaları bu polimerin sahip olduğu geniş uygulama alnından dolayı halen ilgi çekmektedir. Bu çalışmada akrilonitril-bütadien-stiren matrisine asidik pomza tozu ilave edilerek kompozitler hazırlanmıştır. Kompozit hazırlama işlemi aynı yönde dönüş yapan çift vidalı mikrokarıştırıcı ile gerçekleştirilmiş ve test numuneleri enjeksiyon kalıplama ile elde edilmiştir. Asidik pomza parçacıklarının besleme oraları sırası ile %5, %10, %15 ve %20 olarak seçilmiştir. Hazırlanan kompozitlerin karaterizasyonları, çekme dayanımı testi, darbe testi erime akış indisi, dinamik mekanik analiz ve taramalı elektron mikroskobu ile yapılmıştır. Test sonuçlarına göre, kompozitler arasında en yüksek artış % 15 AP eklenmesi ile gözlenmiştir. Bu kompozisyon, ABS/AP kompozitleri için en uygun olarak belirlenmiştir.Article Citation - WoS: 25Citation - Scopus: 27A New Processable and Fluorescent Polydithienylpyrrole Electrochrome With Pyrene Appendages(Pergamon-elsevier Science Ltd, 2013) Tirkes, Seha; Mersini, Jetmire; Oztas, Zahide; Algi, Melek Pamuk; Algi, Fatih; Cihaner, AtillaA new hybrid compound, namely 1-(pyren-3-yl)-2,5-di(thiophen-2-yl)-1H-pyrrole (SNS-P), was polymerized via both chemical and electrochemical methods. Chemically obtained soluble polydithienylpyrrole (c-PSNS-P) bearing pyrene appendages is a homogeneous and uniform polymer with a number averaged molecular weight of 15,200 g/mol. The polymer exhibits both multi-electrochromic and fluorescent properties. Upon oxidation, the color of electrochemically obtained polymer (e-PSNS-P) changes from yellowish orange to greenish yellow and to green/blue and finally to blue. In addition, the polymer induces yellowish orange (564 nm) and bright orange emission (613 nm) in solution and solid states, respectively. (C) 2012 Elsevier Ltd. All rights reserved.Article Citation - WoS: 14Citation - Scopus: 16Electrosynthesis of Polyfuran in Acetonitrile-Boron Trifluoride-Ethyl Ether Mixture and Its Device Application(John Wiley & Sons inc, 2007) Tirkes, Seha; Onal, Ahmet M.Electrochemical polymerization of furan was achieved in acetonitrile/boron trifluoride/ethyl ether (CH3 CN/BF3/EE) mixture in the presence of tetrabutylammonium tetrafluoroborate via constant potential electrolysis at 1.4 V versus Ag/AgCl. Electrochemical behavior of furan was investigated in the same solvent mixture of varying ratios, utilizing cyclic voltammetry. Free-standing polyfuran (PFu) films were obtained in CH3CN/BF3/EE mixture (2/4/4; v/v/v) and characterized using FTIR spectroscopic technique. Spectroelectrochemical behavior of the PFu film was investigated by recording the electronic absorption spectra, in sitn, in monomer-free solution. It is observed that PFu film can be reversibly cycled between -0.1 V (gray) and + 0.6 V versus Ag-wire (gray color); however, this behavior diminishes in the presence of water. Electrochromic device application of PFu film with poly(ethylene dioxythiophene) was also studied. (c) 2006 Wiley Periodicals, Inc.