Lotfısadıgh, Bahram

Loading...

Profile URL

Name Variants

Lotfisadigh, B.

Lotfısadıgh, Bahram

Bahram, Lotfısadıgh

Lotfisadigh, Bahram

L.,Bahram

B.,Lotfisadigh

L., Bahram

Bahram, Lotfisadigh

B., Lotfisadigh

B.,Lotfısadıgh

Lotfısadıgh,B.

Lotfisadigh,B.

Sadigh, Bahram Lotfi

Lotfısadıgh, Bahram

Bahram, Lotfısadıgh

Lotfisadigh, Bahram

L.,Bahram

B.,Lotfisadigh

L., Bahram

Bahram, Lotfisadigh

B., Lotfisadigh

B.,Lotfısadıgh

Lotfısadıgh,B.

Lotfisadigh,B.

Sadigh, Bahram Lotfi

Job Title

Doktor Öğretim Üyesi

Email Address

bahram.lotfisadigh@atilim.edu.tr

Main Affiliation

Manufacturing Engineering

Status

Former Staff

Website

ORCID ID

Scopus Author ID

Turkish CoHE Profile ID

Google Scholar ID

WoS Researcher ID

Sustainable Development Goals

2

ZERO HUNGER

0

Research Products

11

SUSTAINABLE CITIES AND COMMUNITIES

1

Research Products

14

LIFE BELOW WATER

0

Research Products

6

CLEAN WATER AND SANITATION

0

Research Products

1

NO POVERTY

0

Research Products

5

GENDER EQUALITY

0

Research Products

9

INDUSTRY, INNOVATION AND INFRASTRUCTURE

6

Research Products

16

PEACE, JUSTICE AND STRONG INSTITUTIONS

0

Research Products

17

PARTNERSHIPS FOR THE GOALS

0

Research Products

15

LIFE ON LAND

1

Research Products

10

REDUCED INEQUALITIES

0

Research Products

7

AFFORDABLE AND CLEAN ENERGY

0

Research Products

8

DECENT WORK AND ECONOMIC GROWTH

0

Research Products

4

QUALITY EDUCATION

0

Research Products

12

RESPONSIBLE CONSUMPTION AND PRODUCTION

1

Research Products

3

GOOD HEALTH AND WELL-BEING

1

Research Products

13

CLIMATE ACTION

0

Research Products

This researcher does not have a Scopus ID.

This researcher does not have a WoS ID.

Scholarly Output

22

Articles

12

Views / Downloads

141/2129

Supervised MSc Theses

5

Supervised PhD Theses

1

WoS Citation Count

227

Scopus Citation Count

276

WoS h-index

11

Scopus h-index

12

Patents

0

Projects

0

WoS Citations per Publication

10.32

Scopus Citations per Publication

12.55

Open Access Source

5

Supervised Theses

6

Google Analytics Visitor Traffic

| Journal | Count |

|---|---|

| Machining Science and Technology | 3 |

| International Journal of Computer Integrated Manufacturing | 2 |

| Procedia CIRP | 2 |

| The International Journal of Advanced Manufacturing Technology | 2 |

| Artificial Intelligence for Engineering Design, Analysis and Manufacturing: AIEDAM | 1 |

Current Page: 1 / 3

Scopus Quartile Distribution

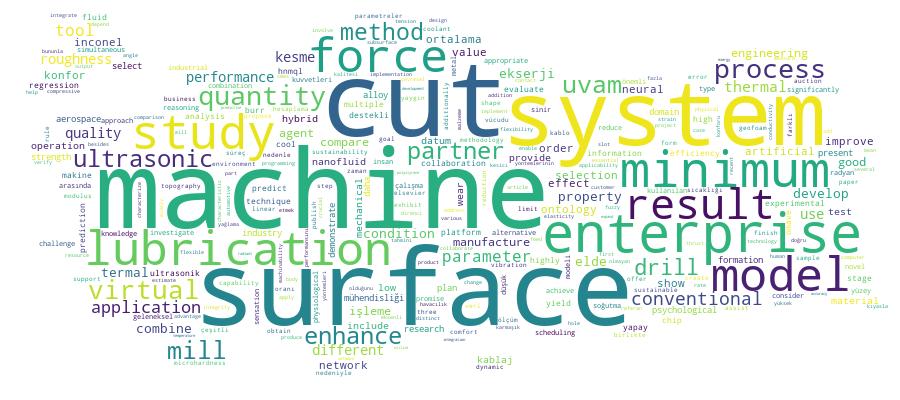

Competency Cloud

22 results

Scholarly Output Search Results

Now showing 1 - 10 of 22

Article Citation - WoS: 15Citation - Scopus: 20A Survey of Partner Selection Methodologies for Virtual Enterprises and Development of a Goal Programming-Based Approach(Springer London Ltd, 2016) Nikghadam, Shahrzad; Sadigh, Bahram Lotfi; Ozbayoglu, Ahmet Murat; Unver, Hakki Ozgur; Kilic, Sadik EnginA virtual enterprise (VE) is a platform that enables dynamic collaboration among manufacturers and service providers with complementary capabilities in order to enhance their market competitiveness. The performance of a VE as a system depends highly on the performance of its partner enterprises. Hence, choosing an appropriate methodology for evaluating and selecting partners is a crucial step toward creating a successful VE. In this paper, we begin by presenting an extensive review of articles that address the VE partner selection problem. To fill a significant research gap, we develop a new goal programming (GP)-based approach that can be applied in extreme bidding conditions such as tight delivery timelines for large demand volumes. In this technique, fuzzy analytic hierarchy process (F-AHP) is used to determine customer preferences for four main criteria: proposed unit price, on-time delivery reliability, enterprises' past performance, and service quality. These weights are then incorporated into the GP model to evaluate bidders based on customers' preferences and goals. We present a case study in which we implement the F-AHP-GP technique and verify the model's applicability, as it provides a more flexible platform for matching customers' preferences.Article Citation - WoS: 13Citation - Scopus: 14Integration of Psychological Parameters Into a Thermal Sensation Prediction Model for Intelligent Control of the Hvac Systems(Elsevier Science Sa, 2023) Turhan, Cihan; Ozbey, Mehmet Furkan; Lotfi, Bahram; Akkurt, Gulden GokcenConventional thermal comfort models take physiological parameters into account on thermal comfort models. On the other hand, psychological behaviors are also proven as a vital parameter which affects the thermal sensation. In the literature, limited studies which combine both physiological and psychological parameters on the thermal sensation models are exist. To this aim, this study develops a novel Thermal Sensation Prediction Model (TSPM) in order to control the HVAC system by considering both parameters. A data-driven TSPM, which includes Fuzzy Logic (FL) model, is developed and coded using Phyton language by the authors. Two physiological parameters (Mean Radiant Temperature and External Temperature) and one psychological parameter (Emotional Intensity Score (EIS) including Vigour, Depression, Tension with total of 32 subscales) are selected as inputs of the model. Besides the physiological parameters which are decided intentionally considering a manual ventilated building property, the most influencing three sub- psychological parameters on thermal sensation are also selected in the study. While the physiological parameters are measured via environmental data loggers, the psychological parameters are collected simultaneously by the Profile of Mood States questionnaire. A total of 1159 students are participated to the questionnaire at a university study hall between 15th of August 2021 and 15th of September 2022. The results showed that the novel model predicted Thermal Sensation Vote (TSV) with an accuracy of 0.92 of R2. The output of this study may help to develop an integrated Heating Ventilating and Air Conditioning (HVAC) system with Artificial Intelligence - enabled Emulators that also includes psychological parameters.Doctoral Thesis Havacılık Endüstrisinde Kullanılan Kesilmesi Zor Malzemeler Üzerinde Nanoakışkan Minimum Miktar Yağlama ile Çok Eksenli Ultrasonik Titreşi̇m Destekli Frezelemenin Etkileri Üzerine Bir İnceleme(2023) Namlu, Ramazan Hakkı; Lotfi, Bahram; Kılıç, Sadık EnginHavacılık sektörü, modern dünyanın önde gelen endüstrilerinden biri olarak öne çıkmaktadır. Bu sektörde Ti-6Al-4V malzemesinin yaygın olarak kullanılması, mükemmel mukavemet-ağırlık oranına ve iyi korozyon direnci gibi özelliklerine sahip olmasından kaynaklanmaktadır. İşleme, malzemeyi nihai şekline dönüştürmek için havacılık sektöründe vazgeçilmez bir süreçtir. Bununla birlikte, Ti-6Al-4V'nin işlenebilirliği, Geleneksel İşleme (Gİ) kapsamında, düşük termal iletkenliği, kesici takımlara yapışma eğilimi ve talaş kaldırmayla ilgili zorluklarla karakterize edilmekte ve bundan dolayı genellikle 'işlenmesi zor' bir malzeme olarak adlandırılmaktadır. İşleme verimliliğini artırmak için, Ultrasonik Titreşim Destekli İşleme (UTDİ) umut vaat eden bir teknik olarak ortaya çıkmıştır. UTDİ, yüksek frekansta, düşük genlikli titreşimleri çeşitli kesme yönlüklerine entegre ederek verimliliği artırmayı amaçlayan hibrit bir işleme yaklaşımıdır. Hibrid işleme stratejileri ile beraber, Ti-6Al-4V'nin işleme performansını artırmak için başka bir yol da soğutma sistemlerini içermektedir. Bu sistemler, malzemenin düşük termal iletkenliğinden kaynaklanan kesme bölgesindeki ısı birikimini azaltmayı amaçlar. Ancak, Geleneksel Kesme Sıvıları'nın (GKS) kullanımı, sınırlı performans artışları ve çevresel ve mesleki sağlık riskleri nedeniyle alternatif tekniklerle değiştirilmektedir. Bu alternatifler arasında, Minimum Miktar Yağlama (MMY), kesme bölgesine yüksek basınçlı hava ile birlikte minimum miktarda yağın aerosol formunda verilmesini içeren bir yöntem olarak ortaya çıkmıştır. Aerosol form, GKS'ye kıyasla kesici takım ile iş parçası arasına daha iyi penetre ederek verimliliğin artmasına katkıda bulunur. Ayrıca, MMY'nin avantajları, Nanoakışkan-MMY (NMMY) olarak bilinen nanoparçacıkların eklenmesi ile daha da artırılmaktadır. NMMY, MMY'de kullanılan yağa nanoparçacıkların entegre edilmesini içerir ve bunların termo-fiziksel özelliklerini kullanarak saf MMY'ye kıyasla üstün işleme verimliliği elde etmeyi amaçlar. Özellikle, en büyük gelişmeler, çeşitli nanoparçacık türlerini birleştiren Hibrid-NMMY (HNMMY) uygulamasıyla elde edilebilir. Bu tez, optimum konsantrasyonları ve uygulama metodolojilerini belirlemek amacıyla, değişik nanoparçacık konsantrasyonları ve bunlara karşılık gelen etkilerle karakterize edilen çeşitli nanoakışkanların kapsamlı bir incelemesini amaçlar. Daha sonra, tez, çok eksenli UTDİ ve NMMY yaklaşımlarının birleşik etkilerini araştırır. Mevcut literatüre göre, daha önce hiçbir araştırma, Ti-6Al-4V üzerinde kanal frezeleme operasyonlarında çok eksenli UTDİ ve NMMY/HNMMY uygulamalarını incelememiştir. Araştırma bulguları, çok eksenli UTDİ ve NMMY'nin birleşik kullanımının Ti-6Al-4V'nin işleme performansında önemli gelişmelere yol açtığını göstermektedir, bu da daha etkili ve sürdürülebilir bir uygulama sağlamaktadır.Conference Object Citation - WoS: 11Citation - Scopus: 12Multi-Axial Ultrasonic Vibration-Assisted Machining of Inconel 718 Using Al2O3-CuO Hybrid Nanofluid MQL(Elsevier Science BV, 2024) Namlu, Ramazan Hakki; Lotfi, Bahram; Kilic, Sadik EnginInconel 718 is a widely used superalloy in the aerospace industry, owing to its exceptional creep and corrosion resistance, as well as its ability to retain strength at elevated temperatures. However, its machinability presents challenges due to its low thermal conductivity and high work hardening rate during conventional machining, resulting in inadequate surface quality. To address this issue, a recent technique known as Ultrasonic Vibration-Assisted Machining (UVAM) has emerged. UVAM involves applying high-frequency, low-amplitude vibrations to the cutting tool or workpiece. Additionally, Minimum Quantity Lubrication (MQL) has been considered as an alternative cooling technique to enhance machining performance. Optimizing the performance of UVAM can be achieved by employing various vibration axes. Additionally, the effectiveness of MQL can be enhanced through the utilization of nanofluids. This study investigates the combined application of multi-axis UVAM and Al2O3-CuO added Hybrid Nanofluid MQL (HNMQL) during the milling of Inconel 718. The evaluation parameters include surface roughness, topography, burr formations, and cutting forces. The results demonstrate that the simultaneous use of multi-axis UVAM and HNMQL significantly improves the machining performance of Inconel 718. This combination leads to better surface quality and overall process efficiency, offering promising prospects for the aerospace industry and other applications involving difficult-to-cut materials. (c) 2024 The Authors. Published by Elsevier B.V.Article Citation - WoS: 25Citation - Scopus: 26Machining Performance and Sustainability Analysis of Al2o3< Hybrid Nanofluid Mql Application for Milling of Ti-6al(Taylor & Francis inc, 2024) Lotfi, Bahram; Namlu, Ramazan Hakki; Kilic, S. EnginMachining of Ti-6Al-4V presents challenges due to its low thermal conductivity, and conventional cutting fluids (CCF) are inadequate in providing a productive and sustainable solution. This study aims to achieve more sustainable and productive machining of Ti-6Al-4V by utilizing Al2O3 and CuO-added Nanofluid Minimum Quantity Lubrication (NMQL) individually and in hybrid form with different concentrations. A comparison is made with pure-MQL, CCF and dry conditions. The study consists of three stages. In the first stage, the physical properties of the coolants, like contact angle and surface tension, are investigated. The second stage involves slot milling operations, and various outputs including cutting forces, surface roughness, surface topography, surface finish, and subsurface microhardness are analyzed. In the last stage, a sustainability analysis is conducted based on the Pugh Matrix Approach. The results indicate that Al2O3-NMQL exhibits lower contact angles and surface tensions compared to other conditions. Furthermore, HNMQL applications result in lower cutting forces (up to 46.5%), surface roughness (up to 61.2%), and microhardness (up to 6.6%), while yielding better surface finish and topography compared to CCF. The sustainability analysis demonstrates that HNMQL application is the most suitable option for achieving sustainable machining of Ti-6Al-4V.Article Citation - WoS: 39Citation - Scopus: 41Enhancing Machining Efficiency of Ti-6al Through Multi-Axial Ultrasonic Vibration-Assisted Machining and Hybrid Nanofluid Minimum Quantity Lubrication(Elsevier Sci Ltd, 2024) Namlu, Ramazan Hakki; Lotfi, Bahram; Kilic, S. EnginTi-6Al-4V offers a balance of good strength with lightweight properties. Yet, Ti-6Al-4V poses machining challenges, including low thermal conductivity, chemical adhesion to cutting tools, and chip removal difficulties. To improve machining efficiency, Ultrasonic Vibration-Assisted Machining (UVAM) has emerged as a promising approach. UVAM has demonstrated reduced tool wear, cutting forces, and improved surface quality compared to Conventional Machining (CM). Additionally, Minimum Quantity Lubrication (MQL) methods offer sustainable coolant alternatives, with recent research focusing on Nanofluid-MQL (NMQL) and Hybrid Nanofluid-MQL (HNMQL) for enhanced performance. Although there exists a body of literature showcasing the promising effects of UVAM and MQL methods individually, comprehensive investigations into the synergistic effects of these methodologies remain limited. This study addresses these critical research gaps by conducting a systematic examination of combined application of multi-axial UVAM and HNMQL. Specifically, it delves into the comparison of different vibration directions within UVAM, evaluates the effectiveness of UVAM when combined with cutting fluids incorporating Al2O3 and CuO nanoparticles in NMQLs and HNMQLs, and contrasts these novel approaches with conventional machining methods. The study unfolds in three distinct stages. The first stage examines the ultrasonic cutting mechanism and its combined application with the MQL technique. In the second stage, the study investigates the physical properties of the cutting fluids, including contact angle and surface tension. The final stage encompasses slot milling operations, where an array of parameters such as cutting forces, surface roughness, surface topography, surface texture, and the occurrence of burr formations are rigorously analyzed. The results demonstrate that the combination of multi-axial UVAM with HNMQL yields substantial advantages over traditional machining methods. Notably, it leads to a remarkable reduction in cutting forces (up to 37.6 %) and surface roughness (up to 37.4 %). Additionally, this combination engenders the production of highly homogeneous and uniform surface textures, characterized by minimal surface defects and a significantly diminished occurrence of burr formations. These findings underscore the potential of multi-axial UVAM combined with HNMQL as a promising approach in enhancing the machining of Ti-6Al-4V, thus offering a pathway to enhance the efficiency and precision of aerospace component manufacturing processes.Conference Object Citation - WoS: 20Citation - Scopus: 25An Experimental Study on Surface Quality of Al6061-T6 in Ultrasonic Vibration-Assisted Milling with Minimum Quantity Lubrication(Elsevier Science BV, 2022) Namlu, Ramazan Hakki; Yilmaz, Okan Deniz; Lotfisadigh, Bahram; Kilic, S. EnginAl6061-T6 is frequently used in the automotive and aerospace industries, where milling is an essential process, due to its high strength-to-weight ratio. In order to achieve improved surface quality in milling, Ultrasonic Vibration-Assisted Milling (UVAM) has been introduced recently. Besides, Minimum Quantity Lubrication (MQL) is another advanced method to enhance the surface properties of the cutting by improving the coolant performance. However, the effects of simultaneous implementation of UVAM and MQL methods has not yet been studied sufficiently. This paper investigates the effects of applying UVAM in tandem with MQL in cutting of Al6061-T6. The results showed that surface quality enhanced with this combination. (c) 2022 The Authors. Published by Elsevier B.V. This is an open access article under the CC BY-NC-ND license (https://creativecommons.org/licenses/by-nc-nd/4.0)Master Thesis Ayrık Üretim Sistemlerinde Kestirimci Bakım için Akıllı Süreç Planlama Uygulaması(2022) Al-humaırı, Elaf Rıyadh Resen; Lotfısadıgh, Bahram; Amınbakhsh, SamanSıkı küresel pazar rekabeti ve sürekli değişen müşteri talepleri, üretim işletmelerini esnek üretim sistemlerine doğru itmektedir. Bu şekilde, süreç planlama ve çizelgeleme adımları üreticiler için gerçekten çok önemlidir. Özellikle hacim ve ürün tipi esnekliği olan esnek atölyelerde bu süreçler daha da kritik hale geliyor. 'Endüstri 4.0' adı verilen yeni bir sanayi devrimi, işletmelerin bu ezici rekabet baskısı ile yüzleşmelerini desteklemek ve süreç planlama ve çizelgeleme süreçlerinin verimliliğini artırmak için bilgisayar ve bilgi teknolojilerini üretim sistemleriyle entegre ederek yeni teknolojik olanaklar getiriyor. Etmen tabanlı sistemler, üretim sistemlerinin sanallaştırılması, siber-fiziksel katmanların oluşturulmasıyla sistem simülasyonu, dijital ikizler ve diğerleri gibi bu teknolojilerden bazıları literatürde çeşitli araştırmalarda çalışılmış ve geliştirilmiş olarak adlandırılabilir. Bu araştırmada, üretim alanının ontolojik modellemesi ve muhakeme kurallarının süreç planlama aşamasına bir çözüm olarak Lekin çizelgeleme programı ile entegre edilerek yeni bir metodoloji önerilmiştir. Bu tezde, önce talaşlı imalat işlemleri için geliştirilen ontoloji etki alanı modeli anlatılmış, daha sonra tasarlanarak eklenen muhakeme kuralları ve SPARQL sorguları detaylı olarak anlatılmıştır. Son olarak, Lekin programı yerleşik sezgisellerinden elde edilen çizelgeleme sonuçları açıklanmıştır.Conference Object Citation - WoS: 10Citation - Scopus: 13A Multi-Agent System Model for Partner Selection Process in Virtual Enterprise(Elsevier Science Bv, 2014) Sadigh, B. Lotfi; Arikan, F.; Ozbayoglu, A. M.; Unver, H. O.; Kilic, S. E.Virtual Enterprise (VE) is a collaboration model between multiple business partners in a value chain. VE information system deals with highly dynamic information from heterogeneous data sources. In order to manage and store dynamic VE information in the database, an ontology based VE model has been developed. To select winner enterprises in VE, a Multi Agent System (MAS) has been developed. Communication and data transition among agents and system entities are based on defined rules in VE ontology model. One of the most important contributions of agents in VE system is in partner selection step of VE formation phase. In this step several agents with different goals and strategies are collaborating and competing each other to win the negotiation procedure or maximize the profit for their assigned enterprise. Different strategies are developed for the agents depending on their appetite for winning the auction against maximizing the profit. Several simulations were run and the results are stored. These results are fed into a neural network in order to predict which enterprise will win the auction and what will be the profit margin. The motivation is to provide a forecasting agent for the customers about the outcomes of the auctions so that they can plan ahead and take the necessary action. Early results indicate such simulated multi-agent VE formations can be used in real systems. A Multi-Agent System Model for Partner Selection Process in Virtual Enterprise (C) 2014 Published by Elsevier B.V.Article Citation - WoS: 7Citation - Scopus: 10Combined Use of Ultrasonic-Assisted Drilling and Minimum Quantity Lubrication for Drilling of Niti Shape Memory Alloy(Taylor & Francis inc, 2023) Namlu, Ramazan Hakki; Lotfi, Bahram; Kilic, S. Engin; Yilmaz, Okan Deniz; Akar, SametThe drilling of shape-memory alloys based on nickel-titanium (Nitinol) is challenging due to their unique properties, such as high strength, high hardness and strong work hardening, which results in excessive tool wear and damage to the material. In this study, an attempt has been made to characterize the drillability of Nitinol by investigating the process/cooling interaction. Four different combinations of process/cooling have been studied as conventional drilling with flood cooling (CD-Wet) and with minimum quantity lubrication (CD-MQL), ultrasonic-assisted drilling with flood cooling (UAD-Wet) and with MQL (UAD-MQL). The drill bit wear, drilling forces, chip morphology and drilled hole quality are used as the performance measures. The results show that UAD conditions result in lower feed forces than CD conditions, with a 31.2% reduction in wet and a 15.3% reduction in MQL on average. The lowest feed forces are observed in UAD-Wet conditions due to better coolant penetration in the cutting zone. The UAD-Wet yielded the lowest tool wear, while CD-MQL exhibited the most severe. UAD demonstrated a & SIM;50% lower tool wear in the wet condition than CD and a 38.7% in the MQL condition. UAD is shown to outperform the CD process in terms of drilled-hole accuracy.

- «

- 1 (current)

- 2

- 3

- »