This item is non-discoverable

Tekkaya, Ahmet Eeman

Loading...

Profile URL

Name Variants

Tekkaya, A. E.

Tekkaya, A. Erman

Tekkaya, AE

A.E.Tekkaya

Tekkaya,A.E.

T.,Ahmet Eeman

A.,Tekkaya

A., Tekkaya

T., Ahmet Eeman

Tekkaya, Ahmet Eeman

Ahmet Eeman, Tekkaya

Tekkaya, E

Tekkaya, E. A.

Tekkaya, A. Erman

Tekkaya, AE

A.E.Tekkaya

Tekkaya,A.E.

T.,Ahmet Eeman

A.,Tekkaya

A., Tekkaya

T., Ahmet Eeman

Tekkaya, Ahmet Eeman

Ahmet Eeman, Tekkaya

Tekkaya, E

Tekkaya, E. A.

Job Title

Profesör Doktor

Email Address

Main Affiliation

Manufacturing Engineering

Status

Former Staff

Website

ORCID ID

Scopus Author ID

Turkish CoHE Profile ID

Google Scholar ID

WoS Researcher ID

Sustainable Development Goals

9

INDUSTRY, INNOVATION AND INFRASTRUCTURE

4

Research Products

This researcher does not have a Scopus ID.

This researcher does not have a WoS ID.

Scholarly Output

31

Articles

14

Views / Downloads

98/131

Supervised MSc Theses

2

Supervised PhD Theses

0

WoS Citation Count

737

Scopus Citation Count

871

WoS h-index

12

Scopus h-index

12

Patents

0

Projects

0

WoS Citations per Publication

23.77

Scopus Citations per Publication

28.10

Open Access Source

1

Supervised Theses

2

Google Analytics Visitor Traffic

| Journal | Count |

|---|---|

| International Journal of Machine Tools and Manufacture | 3 |

| steel research international | 3 |

| 12th International Conference on Sheet Metal (SheMet 2007) -- APR 01-04, 2007 -- Univ Palermo, Palermo, ITALY | 2 |

| AIP Conference Proceedings -- NUMISHEET 2005: 6th International Conference and Workshop on Numerical Simulation of 3D Sheet Metal Forming Processes -- 15 August 2005 through 19 August 2005 -- Detroit, MI | 2 |

| Arabian Journal for Science and Engineering | 2 |

Current Page: 1 / 4

Scopus Quartile Distribution

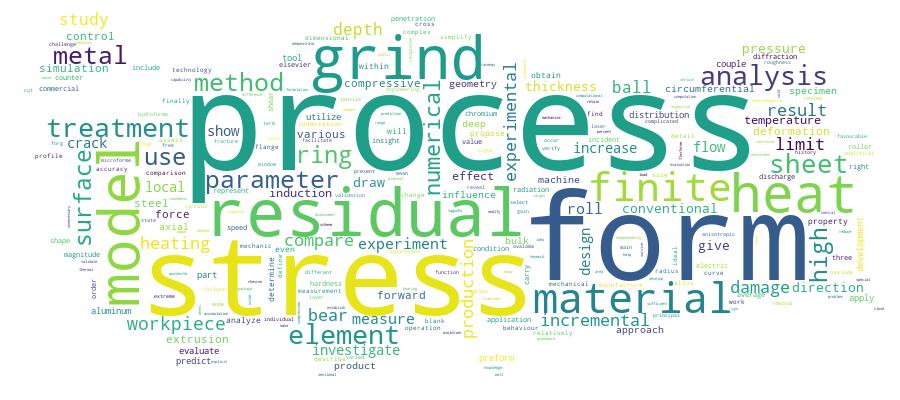

Competency Cloud

31 results

Scholarly Output Search Results

Now showing 1 - 10 of 31

Conference Object Analysis of Force-Indentation Measurements on Anisotropic Metals(Edizioni libreria progetto, 2005) Koray,E.; Topcu,N.; Tekkaya,A.E.Indentation tests are widely used with simultaneous measurements of indentation depth and force especially for determining material properties. In this study, findings on parameters affecting the force-displacement curves obtained from indentations on anisotropic metals using special not self-similar indenters will be presented. Parameters such as specimen dimensions, friction, surface roughness, specimen clamping and indentation spacing have been investigated by finite element analysis and by experiments. Optimum values of these parameters to achieve higher repeatability and accuracy are determined.Article Citation - WoS: 5Citation - Scopus: 6Material Flow Control in High Pressure Sheet Metal Forming of Large Area Parts With Complex Geometry Details(verlag Stahleisen Mbh, 2005) Trompeter, M; Önder, E; Homberg, W; Tekkaya, E; Kleiner, MWorking media based forming processes show advantages compared to the conventional deep drawing in the range of sheet metal parts with complex geometry details. By High Pressure Sheet Metal Forming (HBU), complex parts can be formed with reduced tool costs, fewer process steps, and improved part properties, particularly by the use of high strength steels. In order to use these advantages to full capacity, the material flow into the area of the geometry details needs to be optimised. The key element for the material flow control is a multi-point blank holder. In combination with flange draw-in sensors, a closed loop flange draw-in control can be built up which guarantees a reproducible material flow and, consequently, defined part properties. Furthermore, a favourable pre-distribution of sheet metal material can be reached which leads to a widening of the process limits. Considering a large area sheet metal part with a complex door handle element as example, strategies for the material flow control will be discussed in this paper. The conclusions are based on FE-simulations as well as experimental findings.Article Citation - WoS: 64Citation - Scopus: 69A Semi-Empirical Approach for Residual Stresses in Electric Discharge Machining (edm)(Elsevier Sci Ltd, 2006) Ekmekci, Bulent; Tekkaya, A. Erman; Erden, AbdulkadirHigh residual stresses are developed on the surfaces of electric discharge machined parts. In this study, layer removal method is used to measure the residual stress profile as a function of depth beneath the surface caused by die sinking type EDM. Cracking and its consequences on residual stresses are also studied on samples machined at long pulse durations. A modified empirical equation is developed for scaling residual stresses in machined surfaces with respect to operating conditions. In this model, a unit amplitude shape function representing change in curvature with respect to removal depth is proposed. The proposed form is found to be a special form of a Gauss Distribution. It is the sum of two Gaussian peaks, with the same amplitude and pulse width but opposite center location. The form can be represented by three constant coefficients. These coefficients depend on the released energy by a power function. (C) 2005 Elsevier Ltd. All rights reserved.Article Citation - WoS: 15Finite deformation plasticity coupled with isotropic damage: Formulation in principal axes and applications(Elsevier Science Bv, 2010) Soyarslan, C.; Tekkaya, A. E.A local, isotropic damage coupled hyperelastic-plastic framework is formulated in principal axes. It is shown that, in a functional setting, treatment of many damage growth models, including those originated from phenomenological models (with formal thermodynamical derivations), micromechanics or fracture criteria, proposed in the literature, is possible. As a model problem, a Lemaitre-variant damage model with quasi-unilateral damage evolutionary forms is given with special emphasis on the feasibility of formulations in principal axes. To this end, closed form expression for the inelastic tangent moduli, consistent with the linearization of the closest point projection algorithm, is derived. It is shown that, generally, even in the absence of quasi-unilateral damage evolutionary conditions, the consistent tangent moduli are unsymmetric. The model is implemented as a user defined material subroutine (UMAT) for ABAQUS/Standard. The predictive capability of the selected model problem is studied through axi-symmetric application problems involving forward extrusion of a cylindrical billet, upsetting of a tapered specimen and tension of a notched specimen, in which characteristic failure mechanisms are observed. (C) 2010 Elsevier B.V. All rights reserved.Conference Object Citation - WoS: 11Modeling Flexforming (fluid Cell Forming) Process With Finite Element Method(Trans Tech Publications Ltd, 2007) Hatipoglu, H. Ali; Polat, Naki; Koeksal, Arif; Tekkaya, A. ErmanIn this paper, the flexforming process is modeled by finite element method in order to investigate the operation window of the problem. Various models are established using explicit approach for the forming operation and implicit approach for the unloading one. In all analyses the rubber diaphragm has been modeled revealing that the modeling of this diaphragm is essential. Usine the material Aluminum 2024 T3 alclad sheet alloy, three basic experiments are conducted: Bending of a straight flange specimen, bending of a contoured flange specimen and bulging of a circular specimen. By these experiments tile effects of blank thickness, die bend radius, flange length and orientation of the rolling direction of the part have been investigated. Experimental results are compared with finite element results to verify the computational models.Article Citation - WoS: 119Citation - Scopus: 141The Development of Ring Rolling Technology(verlag Stahleisen Mbh, 2005) Allwood, JM; Tekkaya, AE; Stanistreet, TFA thorough survey of work on ring rolling published in the English and German languages by 2004 is presented. The process is briefly introduced and a set of ideals are stated, as the target for all developments in the area. The main challenges which inhibit attainment of these ideals are given, and the process is compared with alternatives. The main body of the review is organised in four parts: the evolution of the design of ring rolling equipment is described, including detailed discussion of the design and manufacture of preforms; the methods used to investigate the process are reviewed, separated into experimental and theoretical categories; the insights gained from these investigations are organised according to the challenges identified at the outset; developments in the control and operation of the process are described. Having given a set of ideal targets for the process, the state of current knowledge about ring rolling is assessed in order to predict likely developments: process modelling capability is nearly able to predict rolling behaviour for a complete cycle with sufficient accuracy to allow effective use of models for design of rolling schedules and preforms; analysis of material behaviour is relatively mature for steel rings, but has scope for significant extension for titanium and aluminium alloys and composites; design choices that seek to extend the flexibility of the process have had some exploration, but could be extended. Finally, the seminal contribution of Professor Kopp is briefly described.Article Citation - WoS: 14Citation - Scopus: 20Comparison of Various Preforms for Hot Forging of Bearing Rings(Elsevier Science Sa, 2005) Arbak, M; Tekkaya, AE; Özhan, FProduction of bearing rings by hot forging is investigated in this study. The aim of the study is to determine a feasible preform at the first station of the forming process such that the tool wear is prolonged and tool fracture is prevented. For this purpose, it is assumed that the contact pressure at the interface between tools and workpiece is the predominant process parameter. The contact pressures are determined by precise thermo-mechanical coupled finite element analyses based on elastic-plastic material description. Material flow curves for various temperatures and strain-rates are determined in velocity controlled upsetting tests. Cooling experiments are used to determine the heat transfer coefficients. Accuracy of the numerical models has been verified by extensive numerical convergence studies and finally by comparing with experimental measurements. The analysed preforms are evaluated using a scheme of weight-factors for the various tool parts. Finally, a preform is suggested for which the weighted total tool pressure could be reduced by 15%. (c) 2005 Elsevier B.V. All rights reserved.Master Thesis Mikroşekillendirme Analizi: Mikromekanik ve Sayısal Yönleri(2007) Demirci, Emrah; Tekkaya, A. Erman; Soyarslan, Celal; Department of Mechatronics Engineering; Department of Mechatronics Engineering; Department of Mechatronics EngineeringArtan elektronik ve mikromekanik parcaların piyasa hacmi donanımların daha yogun islevsellik kazanmalarına ve kuculmelerine yol acmaktadır. Talepleri karsılamak icin mikro-parcaların uretim yontemlerinin tasarımı hem uygulamalı ve hem de analitik olarak arastırılmalıdır. Bu tez mikro-¸sekillendirmenin analitik olarak arastırılmasına katkıda bulunmak icin hazırlanmıstır. Mikro-¸sekillendirme yontemlerinin sonlu elemanlar yontemi ile simulasyonu icin basitlestirilmis bir modelleme yaklasımı onerilmistir. Yeni modelleme yaklasımı boyut etkileri diye adlandırılan geleneksel sekillendirme ve mikro-¸sekillendirme arasındaki farkları acıklamayı hedefler. Azalan is parcası ebat olcegi nedeniyle olusan boyut etkileri malzemenin homojen olmayan tanecik yapısı ile acıklanmıstır. Sonucta sonlu elemanlar yontemi simulasyonu icin onerilen yaklasım, malzemeyi anisotropik mekanik ozelliklere sahip bireysel tanecikler olarak modellemektir. Taneciklerin yonsel tepkileri Hill'in anizotropik malzeme modeli ile temsil edilmistir. Uc mumkun malzeme modeli (izotropik, tek tanecik, ¸coklu tanecik) ile 2 ve 3 boyutlu yaygın sekillendirme yontemlerinin sim¨ulasyonları yapılmı¸stır ve literat¨ur ile kar¸sıla¸stırılmı¸stır. Dahası, konsept bir mikro-¸sekillendirme presi i¸ceren bir deney duzenegi tasarlanmı¸stır. Anahtar sozcukler : Mikro-¸sekillendirme, Geleneksel ¸sekillendirme, Boyut etkileri, Hill'in anizotropik malzeme modeli, Sonlu elemanlar y¨ontemi.Article Citation - WoS: 17Citation - Scopus: 19Prevention of Internal Cracks in Forward Extrusion by Means of Counter Pressure: a Numerical Treatise(verlag Stahleisen Mbh, 2009) Soyarslan, C.; Tekkaya, A. E.In the context of forward bulk extrusion, where product defects are frequently observed, the effect of counter pressure on damage accumulation materializing a Continuum Damage Mechanics (CDM) approach is presented. A Lemaitre variant damage model accounting for unilateral damage evolution coupled with a multiplicative finite plasticity is utilized for this purpose. After a presentation of the crack governing mechanism, it is demonstrated that application of counter pressure introduces a marked decrease in the central damage accumulation, which in turn increases the formability of the material through keeping the tensile triaxiality in tolerable limits. It is also shown that, for a crack involving process, through systematic increase of the counter pressure, the crack sizes diminish; and at a certain level of counter pressure chevron cracks can be completely avoided.Article Citation - WoS: 6Citation - Scopus: 10Generalized transient temperature behavior in induction heated workpieces(Elsevier Science Sa, 2009) Okman, Oya; Dursunkaya, Zafer; Tekkaya, A. ErmanElectromagnetic-thermal coupled numerical analysis of induction heating is time intensive if three-dimensional models are used. In this study, by processing the results of finite element computations, a dimensional analysis is carried out to predict the transient temperature rise time at the surface of an induction heated workpiece. A unique set of curves is found that describes the transient dimensionless temperature at a point on the surface as a function of the electromagnetic skin depth alone. The effectiveness of the approach is verified by numerical calculations and comparing the dimensionless temperature curves for different heating cases and materials. Effect of temperature dependent thermal properties is also investigated. The consistency of numerical results is also verified by comparison with experiments. (C) 2009 Elsevier B.V. All rights reserved.