Şimşir, Caner

Loading...

Profile URL

Name Variants

C.,Simsir

Simsir, Caner

Şimşir, Caner

C., Simsir

Simsir,C.

C.,Şimşir

S.,Caner

S., Caner

Caner, Simsir

Şimşir,C.

Caner, Şimşir

Ş.,Caner

Simsir, C.

Simsir, Caner

Şimşir, Caner

C., Simsir

Simsir,C.

C.,Şimşir

S.,Caner

S., Caner

Caner, Simsir

Şimşir,C.

Caner, Şimşir

Ş.,Caner

Simsir, C.

Job Title

Doktor Öğretim Üyesi

Email Address

caner.simsir@atilim.edu.tr

Main Affiliation

Manufacturing Engineering

Status

Former Staff

Website

ORCID ID

Scopus Author ID

Turkish CoHE Profile ID

Google Scholar ID

WoS Researcher ID

Sustainable Development Goals

2

ZERO HUNGER

0

Research Products

11

SUSTAINABLE CITIES AND COMMUNITIES

0

Research Products

14

LIFE BELOW WATER

0

Research Products

6

CLEAN WATER AND SANITATION

0

Research Products

1

NO POVERTY

0

Research Products

5

GENDER EQUALITY

0

Research Products

9

INDUSTRY, INNOVATION AND INFRASTRUCTURE

3

Research Products

16

PEACE, JUSTICE AND STRONG INSTITUTIONS

0

Research Products

17

PARTNERSHIPS FOR THE GOALS

0

Research Products

15

LIFE ON LAND

0

Research Products

10

REDUCED INEQUALITIES

0

Research Products

7

AFFORDABLE AND CLEAN ENERGY

0

Research Products

8

DECENT WORK AND ECONOMIC GROWTH

0

Research Products

4

QUALITY EDUCATION

0

Research Products

12

RESPONSIBLE CONSUMPTION AND PRODUCTION

0

Research Products

3

GOOD HEALTH AND WELL-BEING

2

Research Products

13

CLIMATE ACTION

0

Research Products

This researcher does not have a Scopus ID.

This researcher does not have a WoS ID.

Scholarly Output

33

Articles

14

Views / Downloads

143/1590

Supervised MSc Theses

12

Supervised PhD Theses

0

WoS Citation Count

175

Scopus Citation Count

227

WoS h-index

8

Scopus h-index

9

Patents

0

Projects

0

WoS Citations per Publication

5.30

Scopus Citations per Publication

6.88

Open Access Source

6

Supervised Theses

12

Google Analytics Visitor Traffic

| Journal | Count |

|---|---|

| Computational Materials Science | 3 |

| Materialwissenschaft und Werkstofftechnik | 3 |

| Hittite Journal of Science and Engineering | 2 |

| Materials Performance and Characterization | 2 |

| International Conference on the Technology of Plasticity (ICTP) -- SEP 17-22, 2017 -- Cambridge, ENGLAND | 1 |

Current Page: 1 / 3

Scopus Quartile Distribution

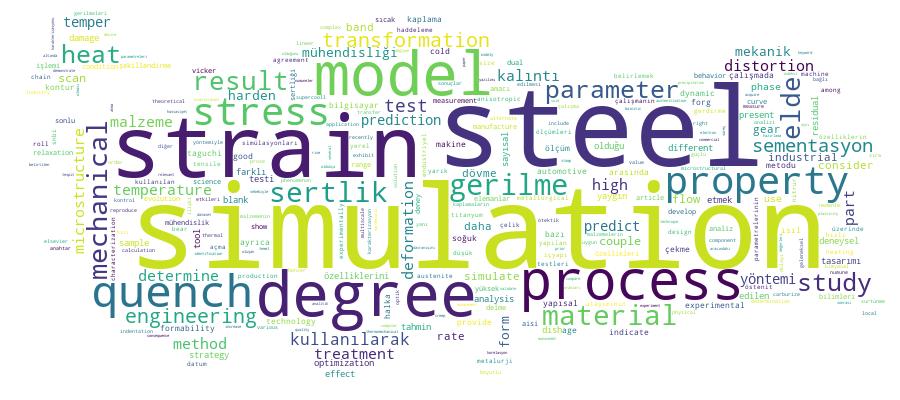

Competency Cloud

33 results

Scholarly Output Search Results

Now showing 1 - 10 of 33

Master Thesis Gerdirerek Şekillendirme İşleminin Deneysel ve Sayısal İncelenmesi(2013) Alkaş, Celal Onur; Karadoğan, Celalettin; Şimşir, CanerGerdirerek şekillendirme operasyonu, yaygın olarak havacılık sektöründe kullanılmakta olan geniş sac panelleri imal etmek için kullanılan bir yöntemdir. Bu prosesin başarısı büyük ölçüde sac malzemenin mekanik özellikleri, takım-iş parçası ara yüzeyindeki sürtünme koşulu, takım ve çenelerin birbirine göre bağıl hareketleri gibi işlem parametrelerine bağlıdır. Deneme yanılma prosedürü ile en iyi proses parametrelerinin tespiti oldukça zor ve maliyetlidir, bu nedenle sonlu elemanlar analizine ihtiyaç duyulmaktadır.Bu çalışmanın amacı, gerdirerek şekillendirme prosesi için sonlu elemanlar modeli (SEM) geliştirmektir. Bu amaç için, hassas malzeme ve güvenilir temas modeli gerekmektedir. Modele girdi oluşturabilmek için, yaygın olarak kullanılan alüminyum alaşımlarına yönelik mekanik malzeme karakterizasyon testleri yürütülmüştür. Alüminyum sac malzemenin deformasyon davranışı ve anizotropik özelliklerini elde etmek için; standart çekme, basma, hidrolik şişirme testi (HŞT) ve şekillendirme sınır diyagramı (ŞSD) testleri gerçekleştirilmiştir. Malzeme deformasyonu süresince, ŞSD'lerin ve HŞT ile akma eğrilerinin tespiti için yüksek çözünürlüklü CCD kameraları kullanılmıştır. Ayrıca, ters analiz tekniği kullanılarak gerdirme operasyonunda karşılaşılan farklı yağlama koşulları için sürtünme katsayılarının tespiti yapılmıştır.Bu girdiler kullanılarak; çene kullanılarak gerdirme, kalıp kullanılarak gerdirme ve senkronize edilmiş takım hareketleri ile gerdirme gibi üç temel gerdirerek şekillendirme takım hareketleri sayısal olarak modellenmiştir.Modelin iyileştirilmesi ve analiz sonuçlarının doğrulanması amacıyla 3-B optik deformasyon ölçüm cihazı olan, GOM-Argus kullanılarak deneysel çalışmalar gerçekleştirilmiştir. Daha sonra, seçilen üç farklı havacılık sac malzemesi analiz edilmiş ve sayısal modelin başarısı endüstriyel uygulamalar için kanıtlanmıştır.Conference Object Citation - WoS: 4Citation - Scopus: 4A Material Perspective on Consequence of Deformation Heating During Stamping of Dp Steels(Iop Publishing Ltd, 2017) Simsir, C.; Cetin, B.; Efe, M.; Davut, K.; Bayramin, B.Recent studies showed that, during stamping of high strength steels at industrially relevant production rates, local temperature in the blank may rise up to 200 degrees C - 300 degrees C due to deformation heating. Moreover, die temperature may also rise up to 100 degrees C - 150 degrees C for progressive stamping dies. Based on the common assumption that the blank softens as the temperature increases, thermal softening creates a margin in Forming Limit Diagram (FLD) and therefore the FLD determined at room temperature can safely be used for those cases. In this article, the validity of this assumption on DP590 steel is questioned by high temperature tensile tests (RT - 300 degrees C) at various strain rates (10(-3) s(-1) - 1 s(-1)). The results indicated a decrease both in uniform and total elongation in 200 degrees C - 300 degrees C range together with several other symptoms of Dynamic Strain Aging (DSA) at all strain rates. Concurrent with the DSA, the simulated FLD confirms the lower formability at high temperature and strain rates. Thus, it is concluded FLD determined at RT may not be valid for the investigated steels.Conference Object Citation - Scopus: 2Fem Modeling of the Distortion of Blank/Case Hardened Gear Blanks Due To Chemical Banding(2012) Şimşir,C.; Hunkel,M.; Lütjens,J.; Rentsch,R.In this study, a FEM process-chain simulation model is presented for the prediction of distortion of blank and case-hardened SAE 5120 (EN 20MnCr5) steel gear blanks. For this purpose, the evolution of the banded microstructure stemming from the continuous casting process was traced by computer simulations of subsequent shape rolling, forging and machining steps. The calculated flow-net was imported into the in-house heat treatment simulation module empowered with the recently developed "Anisotropic Transformation Strain (ATS)" model which enables the inclusion of the effect of banded microstructure on distortion. Then, both blank and case-hardening processes were simulated and verified experimentally. The results indicate good predictions of the dishing directions and dishing-free cutting strategy in both cases; the dishing magnitude is predicted well in blank-hardening simulations while the quality of the prediction is reasonable in case-hardening. Copyright © 2012 ASM International® All rights reserved.Article Citation - WoS: 46Citation - Scopus: 51Multiscale modeling of tempering of AISI H13 hot-work tool steel - Part 1: Prediction of microstructure evolution and coupling with mechanical properties(Elsevier, 2016) Eser, A.; Broeckmann, C.; Simsir, C.In the first part of this two part study, the mechanical properties necessary for the simulation of tempering of an AISI H13 (DIN 1.2344, X40CrMoV5-1) tool steel was derived using physically based precipitation simulations and microstructure-property relationships. For this purpose, the precipitation of fine carbides were simulated using a thermo-kinetic software which allows prediction of the evolution of precipitation/dissolution reactions and the particle sizes. Then, those microstructural findings were coupled with physically based microstructure-property models to predict the yield stress, flow curve and creep properties. The predicted mechanical properties were verified with corresponding experiments and a good agreement was found. In the second part of this study, those properties were coupled with a Finite Element (FE) model in order to predict the relaxation of internal stresses and the evolution of deformations at the macroscopic scale. (C) 2015 Elsevier B.V. All rights reserved.Master Thesis Bor Nitrür Kaplamaların İncelenmesi(2014) Dökmetaş, Nihan; Kaftanoğlu, Bilgin; Şimşir, CanerBu çalışma, Bor Nitrür (BN) kaplama ile ilgili ayrıntılı bilgi vermektedir. Bu çalışmada, fiziksel buhar büyütme (FBB) yöntemiyle radyo frekans (RF) magnetronları saçtırılarak gerçekleşen kaplamada Hekzagonal Bor Nitrür (h-BN) hedef plakası kullanılarak malzemeler üzerinde BN kaplama elde edilmiştir. Kaplamalarda D2 çelikleri, optik camlar, 316L çeliği ve Ti implantlar gibi farklı numuneler kullanılarak farklı alttaşlardaki BN kaplama oluşumları araştırılmıştır. Ayrıca, farklı kaplama parametreleri kullanılarak, parametrelerin BN kaplamadaki etkileri incelenmiştir. Bütün kaplama sonuçları XRD, SEM, Calotest®, Filmetrics F20 İnce film analiz cihazı, adım profilometresi, Çizik Testi, sürtünme testi, sertlik testi, FTIR, AFM ve profilometre kullanılarak araştırılmıştır. BN kaplamaların karakterizasyonu için yapısal, birleşimsel ve mekanik ölçümler ve analizler uygulanmıştır. Yapılan incelemelerde, oluşan kübik bor nitrür (k-BN) kaplamanın yanı sıra a-BN, e-BN, r-BN, w-BN, t-BN ve h-BN gibi yapıların bulunduğu farklı fazlarda BN kaplamaların elde edildiği gözlenmiştir. Tribolojik özellikleri üzerinde kimyasal ve mikro yapısal etkileri araştırıldı. Kaplamaların birden fazla fazda olmasından dolayı yapışkanlık ve sürtünme katsayısına olumlu etkileri gözlemlenmiştir. Bazı durumlarda sertlik artışı gözlenmiştir. Bunun yanı sıra, kaplama kalınlığının 1 µm civarı ve altında olması sebebiyle bazı ölçüm zorluklarıyla karşılaşılmıştır. 3 ve 6 saatlik kaplamaların pürüzlülüğü alttaş pürüzlülüğü ile karşılaştırıldığında istatistiksel olarak anlamlı bir değişiklik tespit edilememiştir Anahtar Kelimeler: Bor Nitrür Kaplama, Fiziksel Buharlaştırma Yöntemi ile Büyütme, RF Magnetron Saçtırması, Bor Nitrür FazlarıEditorial Citation - WoS: 2Citation - Scopus: 2Simulation and Optimization in Materials Technology(Hindawi Ltd, 2014) Guerrero, Martha; Simsir, Caner; Deus, Augusto; Sarler, Bozidar[No Abstract Available]Master Thesis Ti-6al-4v Alaşımının Sıcak Şekillendirmesi için Süreç Haritasının Belirlenmesi(2018) Demirkol, Yasin; Şimşir, CanerTitanyum alaşımları, hafif ve mukavemetli olmalarının yanı sıra korozyona karşı dirençleri sebebiyle havacılık alanında, türbin bıçakları, gaz türbin ve motor parçaları, pervaneler gibi birçok parçanın imalatında kullanılmaktadır. Fakat, bu avantajlardan yararlanabilmek oda sıcaklığındaki düşük süneklikleri nedeniyle, titanyum alaşımlarının genellikle kendine özgü başka sıkıntıları olan yüksek sıcaklık hacimsel ve sac şekillendirme yöntemlerine ihtiyaç duyulmaktadır. Sıcak dövme işlemi bu bileşenlerin imalatı için en yaygın kullanılan yöntemdir. Titanyum sıcak dövme işlemi geleneksel çeliklerin dövme işlemine göre birçok sebepten dolayı daha karmaşıktır: Dövme sırasında oluşabilen akış kararsızlıkları, makro/mikro çatlaklara sebep olması, tane sınırlarında erime ve heterojen içyapı nedeniyle statik ve dinamik mukavemet kaybı, havayla etkileşimden dolayı alfa tabakası oluşumu en sık karşılaşılan problemlerdir. Bunlardan daha önemlisi titanyum dövme sırasında oluşan içyapı birçok çeliğin aksine dövme sonrası yapılan ısıl işlemde onarılamamaktadır. Bu nedenle titanyum dövme işlemi sırf bir şekillendirme işlemi olarak değil, ürüne 'özellik kazandırılan' bir termo-mekanik-metalurjik bir süreç olarak tasarlanmalıdır. Bu çalışmada, Ti-6Al-4V alaşımının sıcak kalıp dövme işleminin yukarıdaki belirtilen şartları sağlayacak şekilde tasarımı için gerekli olan malzeme verisi, deneysel yöntemlerle elde edilmiştir. Malzemenin plastik bölgedeki davranışını belirleyen malzeme yasası parametrelerini belirlemek için geniş yelpazede sıcaklık ve genleme 4 hızı kontrollü basma testleri gerçekleştirilmiştir. Hatasız, istenilen içyapıda dövme ürününün elde edilmesi için deformasyon miktarı ve hızlarını kısıtlayan 'Süreç Haritası' elde edilmiştir.Article Citation - WoS: 4Citation - Scopus: 4Simulation of Through-Hardening of Sae 52100 Steel Bearings - Part Ii: Validation at Industrial Scale(Wiley-v C H verlag Gmbh, 2016) Evcil, G. E.; Mustak, O.; Simsir, C.In this study, the material dataset presented in part I of this article is validated at industrial scale in batch through-hardening of bearing races. The material dataset acquired is implemented in a commercial heat treatment simulation software. Heat transfer coefficients for the oil and salt bath are determined by using a commercial standard quench probe. Zone temperatures and transfer times of the roller-belt furnace are measured directly from the system. Through-hardening of inner ring (IR) of 6813 bearing in oil and salt bath is simulated considering most of the industrial details. Finally, predicted dimensional changes are compared with the coordinate measurement results and a good agreement is achieved. It is concluded that determined material and process data, idealizations and simulation procedure can be considered "validated" for further improvement of the industrial process.Article Transformation Induced Plasticity (trip) of Sae 52100 Steel During Martensitic and Bainitic Transformations(2017) Şimşir, CanerTransformation induced plasticity (TRIP) of SAE 52100 steel during quenching is investigatedboth experimentally and theoretically. TRIP parameter (K) is determinedexperimentally for both martensitic and bainitic transformations by using the stresseddilatometry technique. A new method for extraction of for an incomplete transformationis suggested for the martensitic transformation. Theoretical calculations using wellestablishedmodels for the TRIP effect and the results from the literature are used forthe justification of the results of this work. The results for bainitic transformation isfound to be in good agreement with both the literature and theoretical calculations usingLeblond`s model. On the other hand, experimentally determined value is found to besignificantly different from the literature. Nevertheless, it is still in reasonable agreementwith the calculations using Leblond`s model.Article Citation - Scopus: 2Anisotropic Transformation Strain and Its Consequences on Distortion During Austenitization(Amer Soc Testing Materials, 2012) Simsir, Caner; Lubben, Thomas; Hunkel, Martin; Hoffmann, Franz; Zoch, Hans-WernerThe distribution of segregations, which is introduced in the continuous casting process and modified during succeeding manufacturing steps, is considered as an important "distortion potential carrier" for chemically banded steels. This article presents a recently developed mathematical model for integration of the effect of prior forming and cutting operations into heat-treatment simulations by considering "anisotropic transformation strain (ATS)." The model was justified experimentally by simulating the heating and austenitization of dilatometer specimens machined from the forged discs with distinct orientations with respect to the banded microstructure. After the verification, it is used in conjunction with former experimental work to demonstrate that the distribution of fiber flow is one of the important reasons of the dishing of carburized discs. The model provides promising results for process chain simulation to predict the heat-treatment distortion that cannot be predicted with currently available models.