Keskinkılıç, Ender

Loading...

Profile URL

Name Variants

Keskinkılıç, Ender

Ender, Keskinkilic

Keskinkilic, Ender

E., Keskinkilic

Ender, Keskinkılıç

Keskinkiliç E.

E.,Keskinkılıç

Keskinkılıç,E.

Keskinkilic E.

Keskinkilic, E.

E.,Keskinkilic

K., Ender

K.,Ender

E., Keskinkılıç

Keskinkilic,E.

Ender, Keskinkilic

Keskinkilic, Ender

E., Keskinkilic

Ender, Keskinkılıç

Keskinkiliç E.

E.,Keskinkılıç

Keskinkılıç,E.

Keskinkilic E.

Keskinkilic, E.

E.,Keskinkilic

K., Ender

K.,Ender

E., Keskinkılıç

Keskinkilic,E.

Job Title

Profesor Doktor

Email Address

ender.keskinkilic@atilim.edu.tr

Main Affiliation

Metallurgical and Materials Engineering

Status

Website

ORCID ID

Scopus Author ID

Turkish CoHE Profile ID

Google Scholar ID

WoS Researcher ID

Sustainable Development Goals

2

ZERO HUNGER

0

Research Products

11

SUSTAINABLE CITIES AND COMMUNITIES

0

Research Products

14

LIFE BELOW WATER

1

Research Products

6

CLEAN WATER AND SANITATION

0

Research Products

1

NO POVERTY

0

Research Products

5

GENDER EQUALITY

0

Research Products

9

INDUSTRY, INNOVATION AND INFRASTRUCTURE

2

Research Products

16

PEACE, JUSTICE AND STRONG INSTITUTIONS

0

Research Products

17

PARTNERSHIPS FOR THE GOALS

0

Research Products

15

LIFE ON LAND

0

Research Products

10

REDUCED INEQUALITIES

0

Research Products

7

AFFORDABLE AND CLEAN ENERGY

0

Research Products

8

DECENT WORK AND ECONOMIC GROWTH

0

Research Products

4

QUALITY EDUCATION

0

Research Products

12

RESPONSIBLE CONSUMPTION AND PRODUCTION

0

Research Products

3

GOOD HEALTH AND WELL-BEING

0

Research Products

13

CLIMATE ACTION

0

Research Products

Documents

31

Citations

155

h-index

5

Documents

24

Citations

123

Scholarly Output

30

Articles

13

Views / Downloads

85/0

Supervised MSc Theses

0

Supervised PhD Theses

0

WoS Citation Count

117

Scopus Citation Count

149

WoS h-index

5

Scopus h-index

5

Patents

0

Projects

0

WoS Citations per Publication

3.90

Scopus Citations per Publication

4.97

Open Access Source

6

Supervised Theses

0

Google Analytics Visitor Traffic

| Journal | Count |

|---|---|

| Journal of the Southern African Institute of Mining and Metallurgy | 4 |

| Journal of Mining and Metallurgy, Section B: Metallurgy | 3 |

| 11th International Symposium on High-Temperature Metallurgical Processing -- FEB 23-27, 2020 -- San Diego, CA | 2 |

| Minerals, Metals and Materials Series | 2 |

| 4th International Symposium on High-Temperature Metallurgical Processing held during the 142nd TMS Annual Meeting and Exhibition -- MAR 03-07, 2013 -- San Antonio, TX | 1 |

Current Page: 1 / 5

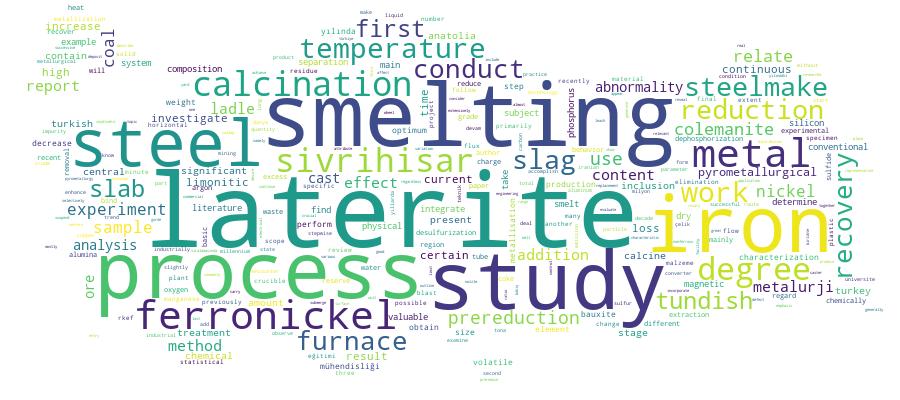

Competency Cloud