Kaftanoğlu, Bilgin

Loading...

Profile URL

Name Variants

Bilgin, Kaftanoğlu

Kaftanoglu, Bilgin

Bilgin Kaftanoğlu

K., Bilgin

Kaftanoğlu,B.

Kaftanoğlu, Bilgin

K.,Bilgin

B.,Kaftanoglu

KAFTANOGLU B.

Kaftanoğlu B.

B.,Kaftanoğlu

Kaftanoglu,B.

Bilgin, Kaftanoglu

Kaftanoglu B.

Kaftanoglu,Bilgin

B., Kaftanoğlu

B., Kaftanoglu

Kaftanoglu, B.

Kaftanoglu, Bilgin

Bilgin Kaftanoğlu

K., Bilgin

Kaftanoğlu,B.

Kaftanoğlu, Bilgin

K.,Bilgin

B.,Kaftanoglu

KAFTANOGLU B.

Kaftanoğlu B.

B.,Kaftanoğlu

Kaftanoglu,B.

Bilgin, Kaftanoglu

Kaftanoglu B.

Kaftanoglu,Bilgin

B., Kaftanoğlu

B., Kaftanoglu

Kaftanoglu, B.

Job Title

Profesör Doktor

Email Address

bilgin.kaftanoglu@atilim.edu.tr

Main Affiliation

Manufacturing Engineering

Status

Website

ORCID ID

Scopus Author ID

Turkish CoHE Profile ID

Google Scholar ID

WoS Researcher ID

Sustainable Development Goals

3

GOOD HEALTH AND WELL-BEING

1

Research Products

7

AFFORDABLE AND CLEAN ENERGY

2

Research Products

9

INDUSTRY, INNOVATION AND INFRASTRUCTURE

4

Research Products

11

SUSTAINABLE CITIES AND COMMUNITIES

1

Research Products

This researcher does not have a Scopus ID.

This researcher does not have a WoS ID.

Scholarly Output

49

Articles

25

Views / Downloads

256/2721

Supervised MSc Theses

10

Supervised PhD Theses

5

WoS Citation Count

744

Scopus Citation Count

832

WoS h-index

13

Scopus h-index

13

Patents

0

Projects

0

WoS Citations per Publication

15.18

Scopus Citations per Publication

16.98

Open Access Source

9

Supervised Theses

15

Google Analytics Visitor Traffic

| Journal | Count |

|---|---|

| Makina Tasarım ve Imalat Dergisi | 3 |

| International Journal of Thermodynamics | 2 |

| CIRP Annals | 2 |

| Applied Energy | 2 |

| International Journal of Refrigeration | 2 |

Current Page: 1 / 5

Scopus Quartile Distribution

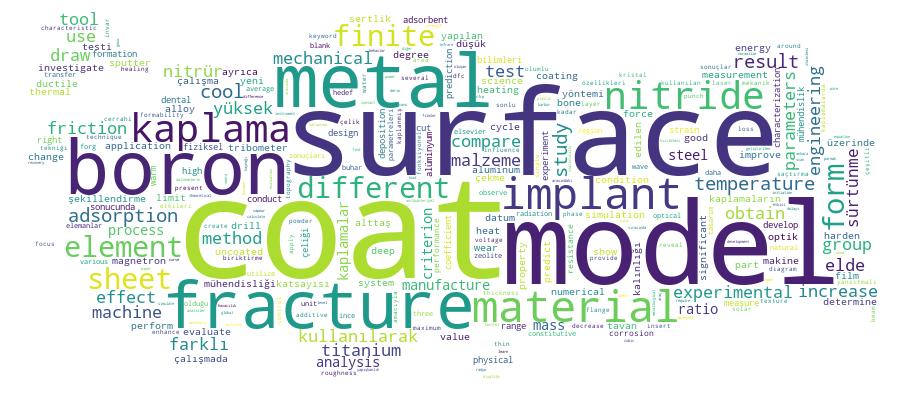

Competency Cloud

49 results

Scholarly Output Search Results

Now showing 1 - 10 of 49

Article Havada Görevlendirilebilen Tekerleksiz Araç Tasarımı – Kişisel Hava Aracı(2022) Küçüköztaş, Korcan; Taşcı, Furkan; Varlı, Hüseyin; Gök, Eren; Kaftanoğlu, Bilgin; Baytaroğlu, ŞakirBu çalışmada, asgari 100kg yük taşıma kapasitesi olan, hafif ve fonksiyonel bir araç tasarımı yapılmıştır. Bu araç, sahip olduğu sekiz pervane sayesinde havada görev görebilirken aynı zamanda yere ve suya dikey iniş de gerçekleştirebilme özelliğine sahiptir. Bu tasarım, kurtarma ekiplerinin ulaşımı, kargo taşımacılığı ve kısa mesafeler içinde, insanların özel ulaşım ihtiyaçlarını karşılayabilmeleri amacı ile tasarlanmıştır. Her pervane motoru tek başına 94kg taşıyabilmekle beraber, aracın toplam taşıyabileceği yük kendi ağırlığıyla birlikte 752kg olmuştur. Proje sürecinde, ön tasarım ve detaylı tasarım süreçleri yürütülmüştür. Tasarımlar, sonlu elemanlar analizleri ve hesaplamalı akışkanlar dinamiği simülasyonlarının sonuçları göz önünde tutularak yapılmıştır. Pervanelerin testi için deneysel iki düzenek tasarlanmıştır. İlk düzenek mekanik bir düzenek olmakla beraber iki taraftan oluşmaktadır. İlk tarafta bir yük hücresi kullanılarak pervanenin itiş gücünün ölçülmesi hedeflenmiştir. İkinci tarafta ise pervanenin dakikada kaç tur attığını ölçmek için bir fotodedektör veya Hall etkisi sensörü kullanılmıştır. İkinci düzenekte bir elektronik hız kontrolcüsü, motoru kontrol etmek için kullanılmıştır. Son olarak, kullanılan yük hücresinin ölçümlemesi için deneysel düzenekler tasarlanmıştır.Letter Theoretical Modelling of Magnetron Sputtering of Boron Nitride Coating(Springer Heidelberg, 2023) Rake, Nakka; Kaftanoglu, Bilgin; Hacaloglu, Tugce; Aydogan, AsudeThe fundamentals of the magnetron sputtering (MS) technique are simple. However, the complex interplay of various physical and chemical sub-processes lies in its simplicity. The direct simulation Monte Carlo (DSMC) method is used to model the MS of the Boron Nitride (BN) coating. The Lorentz force, which is created by an electric field, magnetic field and particle collision, is utilised to model the BN coating. Three distinct bias voltages are used to generate three different BN-coating models under the same conditions. The modelling of BN coatings reveals that the deposition rate decreases as the substrate voltage increases.Master Thesis Yapay Zeka Teknikleri Kullanılarak Bor Nitrür Kaplamalarının Modellenmesi(2025) Küçüköztaş, Korcan; Turhan, Çiğdem; Kaftanoğlu, BilginBor nitrür (BN), yüksek ısıl iletkenlik, düşük sürtünme katsayısı ve yüksek sertlik gibi mükemmel özelliklere sahip bir seramik malzemedir. Ancak, BN kaplamalarının Fiziksel Buhar Biriktirme (FBB) süreci ile Magnetron Saçtırma (MS) tekniği kullanılarak uygulanması, süreç parametreleri ile kaplama özellikleri arasındaki karmaşık etkileşimler nedeniyle zorludur. Bu tez, altı gelişmiş makine öğrenmesi tekniğinden yararlanan Yapay Zeka (YZ) tabanlı bir çerçeve kullanılarak BN kaplama sürecinin modellenmesi ve optimizasyonuna yönelik yenilikçi bir yaklaşım sunmaktadır. Çelik numuneler, farklı kaplama parametreleri ile kaplanmış ve yüksek hassasiyetli ekipmanlarla karakterize edilmiştir. Verileri tanıyabilmek amacıyla, keşifsel veri analizi gerçekleştirilmiştir. Üç farklı kaplama özelliğini tahmin etmek üzere altı farklı mimari kullanılarak makine öğrenmesi modelleri geliştirilmiş ve regresyon değerlendirme metrikleri ile karşılaştırılmıştır. Son olarak, en başarılı modeller, yeni veri setleri üzerinde tahminlerde bulunmak amacıyla kullanılmış ve sonuçlar görselleştirilmiştir. YZ tabanlı yaklaşım, karar verme süresini azaltarak istenilen özelliklere göre en uygun parametrelerinin belirlenmesini sağlamaktadır.Article Havacılık Endüstrisinde Kullanılmak Üzere Alüminyum Malzemelerin Korozyon Direncinin Arttırılması Amacıyla Yüzey Kaplaması Geliştirilmesi(2021) Ceylan, Çağlar; Duran, Bahtiyar; Koçyiğit, Osman; Koçer, Cem; Doğan, Berkay; Hacaloğlu, Tuğçe; Kaftanoğlu, BilginHavacılık endüstrisinde yüksek oranda kullanılan alüminyum alaşımlarını korozyona karşı korumak üzere genellikle kromat (krom VI bazlı) dönüşümlü kaplama (CCC) yöntemleri kullanılmaktadır. Ancak altı değerlikli kromun doğada oluşturduğu zararlı etkilerden dolayı, AB’nin REACH düzenlemeleri ile kullanımı kısıtlanmıştır. Bu çalışma ile krom +6 dönüşümlü kaplamalara alternatif olarak PVD,anodizasyon gibi yöntemlerin de olduğu kaplama çeşitleri araştırılmış ve kaplamaların korozyon dayanımıyla mekanik performansları incelenmiştir.Article Citation - WoS: 58Citation - Scopus: 66Experimental Investigation of a Natural Zeolite-Water Adsorption Cooling Unit(Elsevier Sci Ltd, 2011) Solmus, Ismail; Kaftanoglu, Bilgin; Yamali, Cemil; Baker, DerekIn this study, a thermally driven adsorption cooling unit using natural zeolite-water as the adsorbent-refrigerant pair has been built and its performance investigated experimentally at various evaporator temperatures. The primary components of the cooling unit are a shell and tube adsorbent bed, an evaporator, a condenser, heating and cooling baths, measurement instruments and supplementary system components. The adsorbent bed is considered to enhance the bed's heat and mass transfer characteristics; the bed consists of an inner vacuum tube filled with zeolite (zeolite tube) inserted into a larger tubular shell. Under the experimental conditions of 45 degrees C adsorption, 150 degrees C desorption, 30 degrees C condenser and 22.5 degrees C, 15 degrees C and 10 degrees C evaporator temperatures, the COP of the adsorption cooling unit is approximately 0.25 and the maximum average volumetric cooling power density (SCR,) and mass specific cooling power density per kg adsorbent (SCP) of the cooling unit are 5.2 kW/m(3) and 7 W/kg, respectively. (C) 2011 Elsevier Ltd. All rights reserved.Master Thesis Mikroorganizmaların Yapışmasını Önleyici İnorganik ve Organik Akıllı Yüzeylerin Geliştirilmesi ve İncelenmesi(2014) Ergene, Cansu; Şengönül, Cemal Merih; Kaftanoğlu, BilginÖzellikle uzun süreli kullanımları sırasında tıbbi cihazların yüzeyinde meydana gelen biyofilm oluşumu, hastane ortamında yakalanılan birçok enfeksiyonun temel nedenidir. Çoğu zaman bu enfeksiyonlar, iyileşme sürecini gecikmeye uğratmakta ve sürekli kendisini tekrarlayabilen komplikasyonlar sonucu maliyeti yüksek müdahalelere sebep olmaktadır. Bakteri yapışmasına dirençli yüzeyler hazırlamak, biyofilm oluşumuyla mücadelede etkili bir yaklaşım olabilir. Bu tez çalışmasıyla, mikroorganizmaların yüzeye yapışmasını engelleyici inorganik ve organik akıllı yüzeyler geliştirilmesi hedeflenmiştir. İlk olarak, AISI 316L çelikleri üzerinde kubik ve hekzagonal benzeri kristalografik yapılarda bulunan bor nitrür (BN) kaplamaların bakteriyostatik davranışı incelenmiştir. Bu çalışmada, atomların kristalografik düzenlerinin bakteri yapışmasına etkisi ortaya konmuştur. Organik yüzey çalışmasında ise, katyonik peptit, Laktoferisin B (LFB)'nin kimyasal olarak bağlanmasıyla modifiye edilmiş silikon kauçuğu yüzeylerin antibakteriyel aktiviteleri değerlendirilmiştir. Bu çalışma sonucunda, peptitlerin yüzeye başarılı bir şekilde bağlandıkları ve kataterlerde genellikle biyofilm oluşumuna yol açan S. epidermidis ve P. aeruginosa gibi bakterilere karşı öldürücü etkileri gözlemlenmiştir.Conference Object A Study on the Constitutive Equation Effects in the Fracture Initiation of Aa5450 Sheets(Pleiades journals, 2019) Dizaji,S.A.; Darendeliler,H.; Kaftanoğlu,B.Determination of the fracture initiation in the sheet metal forming applications can be achieved successfully using ductile fracture criteria (DFCs) and finite element codes together. In this study three different uncoupled, energy based ductile fracture criteria have been employed to predict the onset of the fracture in the AA5450 aluminum alloy sheets. Also, two different constitutive models namely, isotropic von-Mises and anisotropic Hill, have been implemented to the finite element code ABAQUS through VUMAT subroutine to investigate the effect of constitutive equations on the applicability of the utilized DFCs. It was shown that the constitutive model has significant influence on the estimation of the time and place of the fracture initiation in the sheets. © Springer Nature Singapore Pte Ltd. 2019.Conference Object Antibacterial Activity of Cubic Boron Nitride (cbn) Coatings on Stainless Steel Grade 316 (316l)(Amer Chemical Soc, 2010) Uzunoglu, Emel; Sengonul, Merih; Derici, Kursat; Biriken, Derya; Kaftanoglu, Bilgin; Sengonul, Merih[No Abstract Available]Article Citation - WoS: 13Citation - Scopus: 13Analysis of Non-Isothermal Warm Deep Drawing of Dual-Phase Dp600 Steel(Springer France, 2019) Pepelnjak, T.; Kayhan, E.; Kaftanoglu, B.Improving the formability of the material is a key issue in the deep drawing process. Heating the material above its recrystallization temperature drastically increases formability, but in the case of dual phase (DP) steels, it results in a loss of their mechanical properties. To improve the drawing ratio, only the heating of the flange region in the warm temperature range up to 573K was studied on DP600 sheet steel by numerical simulation. A thermo-elastic-plastic finite element method (FEM) analysis of deep drawing at several drawing ratios was performed and compared with experimental results. During the experiments, the flange area of the blank was heated by induction heating, and the central part over the punch was cooled with spray water. Experimental results showed that limiting drawing ratio could be increased by 25.58%. The microstructure of the DP 600 steel was analyzed before and after the warm forming process. No significant changes were observed, and the high strength properties of the DP 600 steel remained intact. There was good agreement between numerical and experimental results.Doctoral Thesis Derin Çekme Sınır Oranın, Flanş Bölgesinin Isıtılarak Artırılması için Yöntem Geliştirilmesi(2015) Kayhan, Erdem; Kaftanoğlu, Bilgin; Kayhan, Erdem; Kaftanoğlu, Bilgin; Kayhan, Erdem; Kaftanoğlu, Bilgin; Konca, Erkan; Manufacturing Engineering; Airframe and Powerplant Maintenance; Manufacturing Engineering; Airframe and Powerplant MaintenanceBu tez çalışmasında geliştirilen yöntem kısaca, sac metal malzemelerin şekillendirilme oranının flanş bölgesinin eş sıcaklık dağılımsız ısıtılarak artırılması olarak açıklanabilir. Sıcaklık artışı malzemenin sünekliğinde belirgin bir yükselmeye ve buna bağlı olarak şekillendirilme kapasitesinin artmasına neden olur. Sıcaklık artışı ayrıca malzemenin akma sınırının düşmesi ile birlikte, uygulama kuvvetlerinde ve basınçlarında azalma meydana gelir. Otomotiv endüstrisinde en yaygın kullanıma sahip olan Yüksek Mukavemet Sac Çelik (AHSS) malzeme DP600 olup, araç ağırlıklarının azalmasını ve çarpışma emniyet faktörünün artmasını sağlamasından dolayı bu tez çalışmasında araştırma malzemesi olarak seçilmiştir. Adı geçen çelik malzemelerin kullanımı malzeme kalınlıklarının ve yakıt sarfiyatının azalmasını sağlar. Yapılan araştırmada geliştirilen yöntemin geçerliliği üç farklı tip malzeme, bunlardan iki tanesi Düşük Alaşımlı Yüksek Mukavemet çeliği (HSLA), diğeri ise IF (Arayersiz Çelikler) çeliği kullanılarak, incelenmiştir. Flanş bölgesinin sıcaklığının 180oC to 300oC değerleri arasında oluşturulduğu deneylerde derin çekme sınır oranında %25.58 kadar artış sağlanmıştır. Kullanılan sıcaklık ılık işlem sıcaklığı seviyesinde olduğundan, şekillendirilme kuvvetlerinde azalma meydana gelmesine rağmen malzemenin özelliklerinde ve dayanımında bir değişim gerçekleşmemektedir.